METALMAX EXPOSED FASTENER PANELS

Exposed fastener metal panels are a durable, cost-effective solution for roofing and siding across residential, commercial, and agricultural projects. These panels are installed by driving fasteners directly through the face of the panel into the structure, making installation fast, straightforward, and budget-friendly.

MetalMax offers four exposed fastener panel profiles — PBU Panel, PBR Panel, MaxPanel™, and 5V Crimp — each engineered for specific applications ranging from industrial buildings to barns and homes. With a wide selection of colors, gauges, and rib profiles, our exposed fastener systems deliver reliable performance, weather resistance, and versatile design options. Whether you’re working on new construction or a retrofit, these panels offer long-lasting protection with minimal maintenance.

- Agricultural Buildings

- Commercial Structures

- Industrial Buildings

- Garages and Carports

- Sheds & Storage Barns

- Homes

EXPOSED FASTENER ADVANTAGES

Exposed fastener panels are one of the most affordable metal roofing and siding options, offering long-term durability at a lower upfront cost.

With our PBR and MaxPanel™ having wide 36″ panel coverage and direct screw-through fastening, installation is quick and efficient saving time and labor costs.

Suitable for residential, commercial, agricultural, and light industrial projects, these panels can be installed vertically or horizontally on roofs and walls.

The exposed fastener design allows for straightforward single-panel replacement, making maintenance simple and cost-effective over time.

Made from Galvalume® coated steel and finished with Sherwin-Williams WeatherXL™, these panels resist corrosion, fading, and harsh weather conditions.

Choose from multiple rib profiles and a broad selection of colors to match your building’s design from traditional to modern aesthetics.

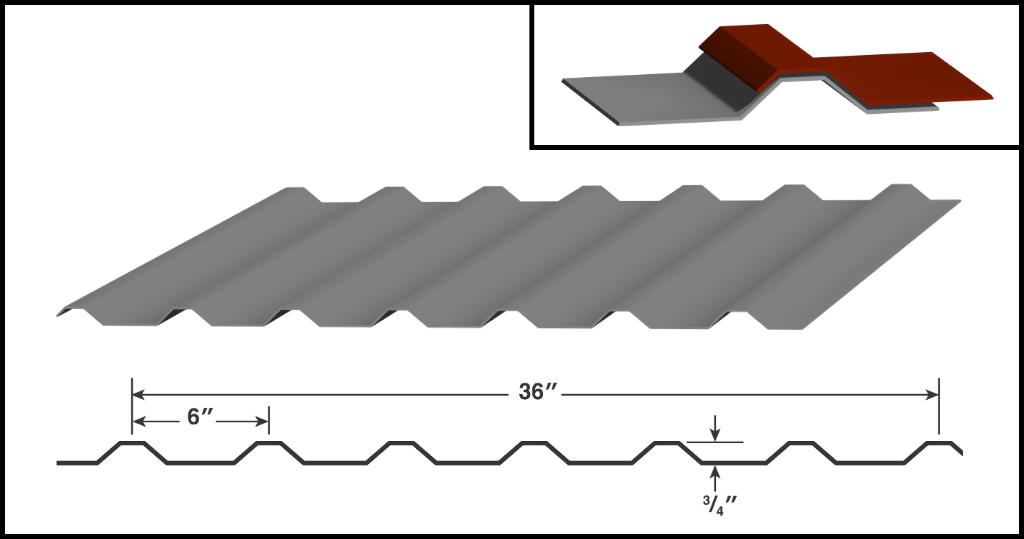

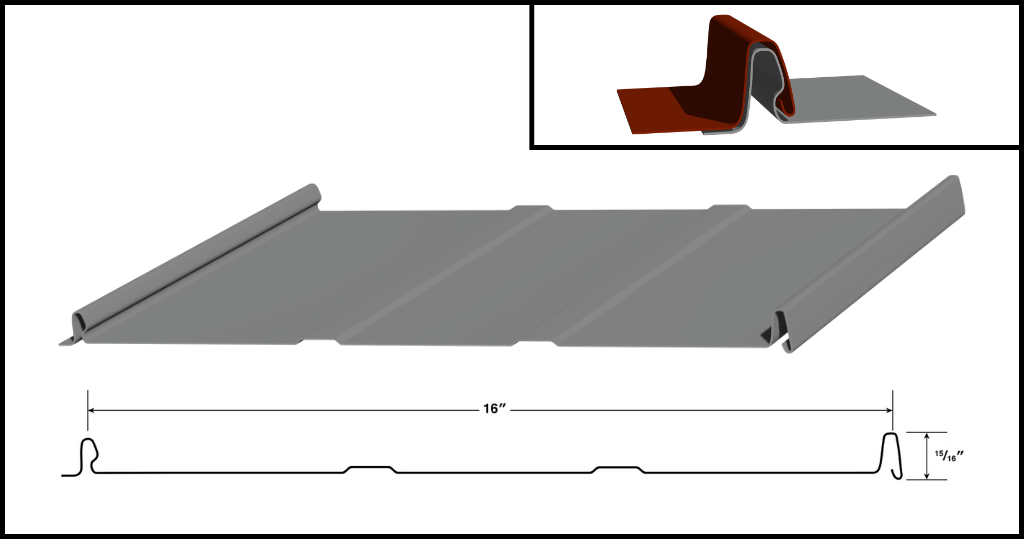

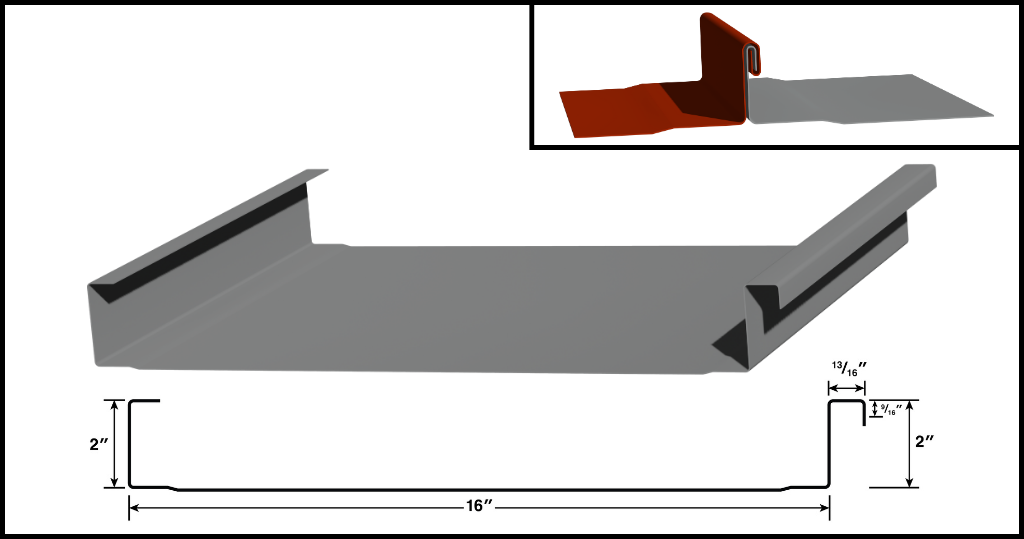

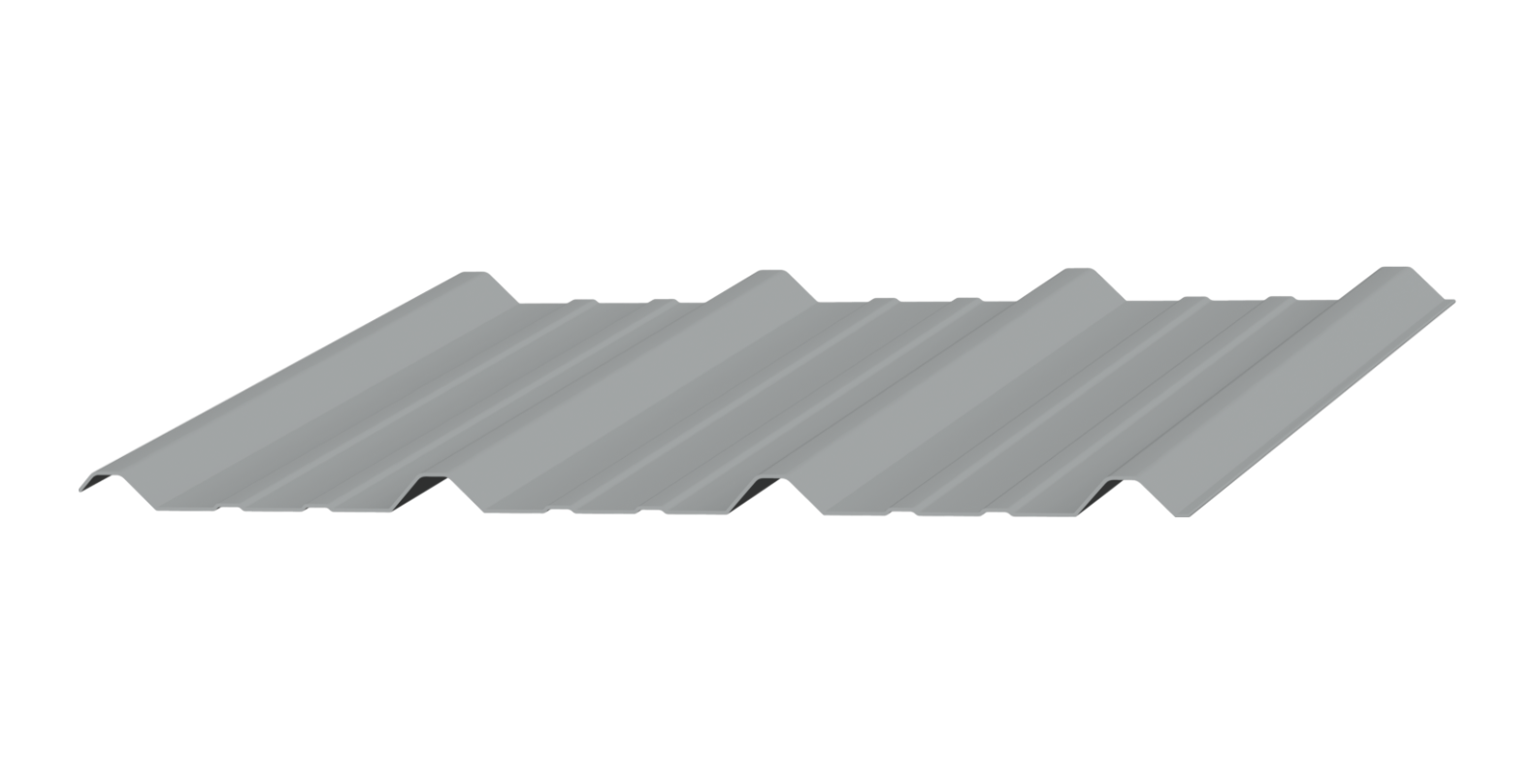

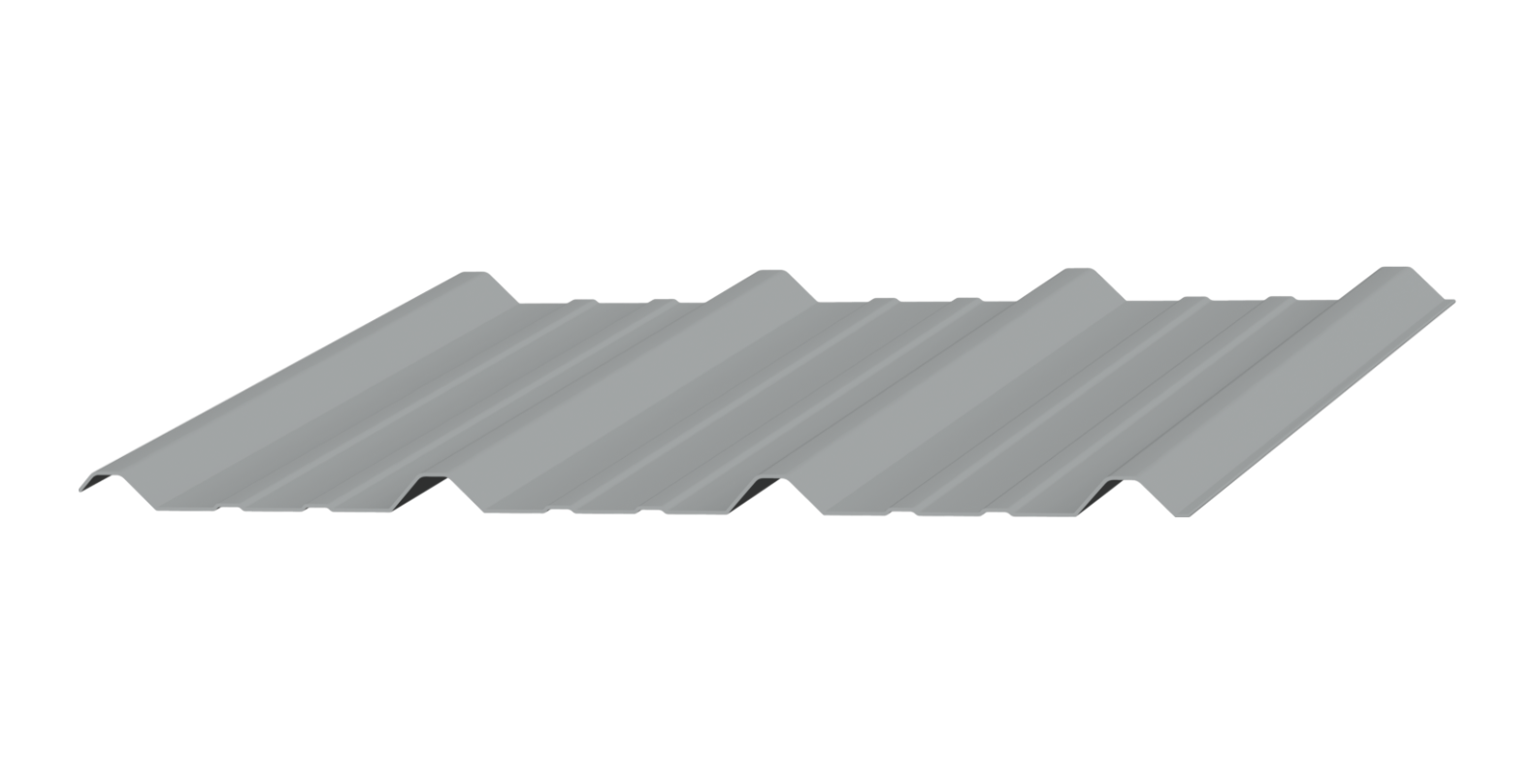

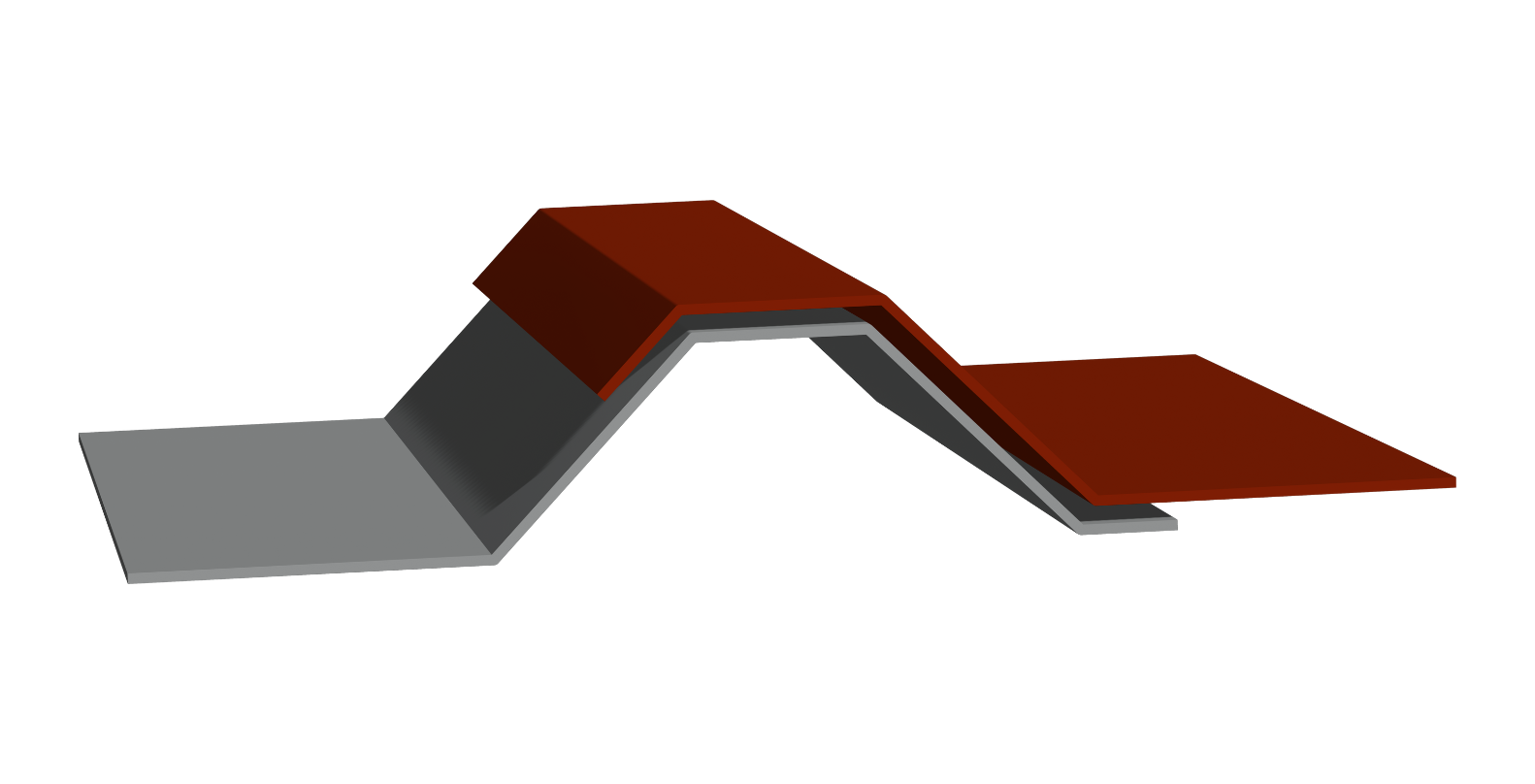

The PBU (Purlin Bearing Underside) Panel is a versatile exposed fastener metal panel designed for roofing and siding applications across commercial, agricultural, and industrial projects. Offering a 36” coverage with ¾” rib height spaced 6” apart, it provides reliable strength and easy installation on both roofs and walls. Its unique purlin-bearing leg ensures consistent alignment and secure fastening, whether installed horizontally or vertically. Manufactured from durable 26-gauge Galvalume® steel and finished with Sherwin-Williams WeatherXL™ coating, the PBU Panel delivers long-lasting color, corrosion resistance, and performance. It is available in a wide range of colors to complement your building’s design.

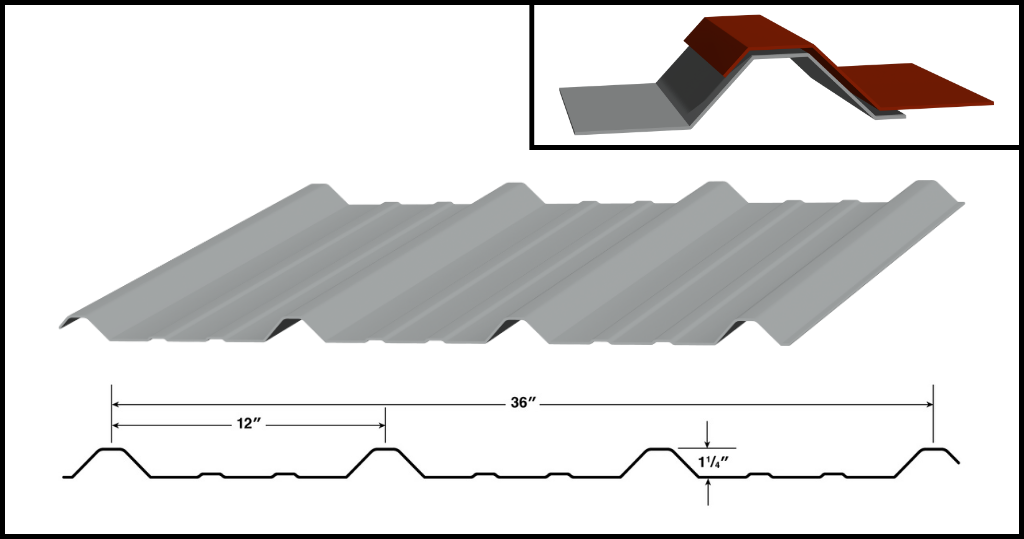

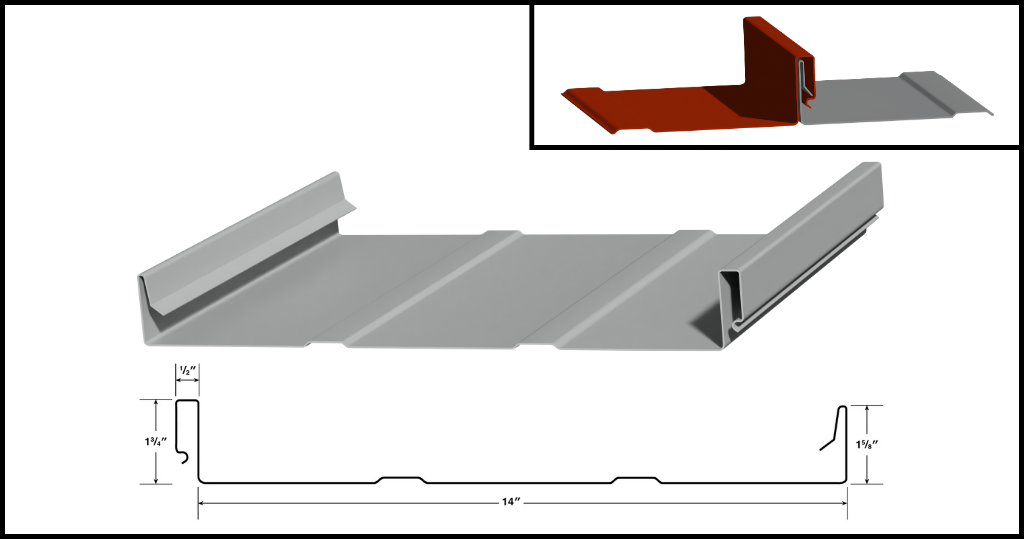

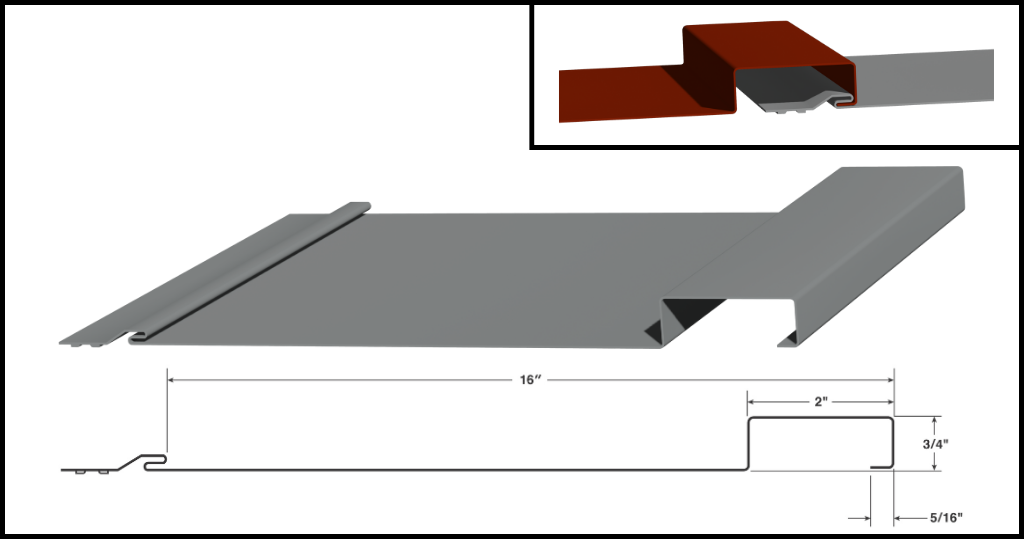

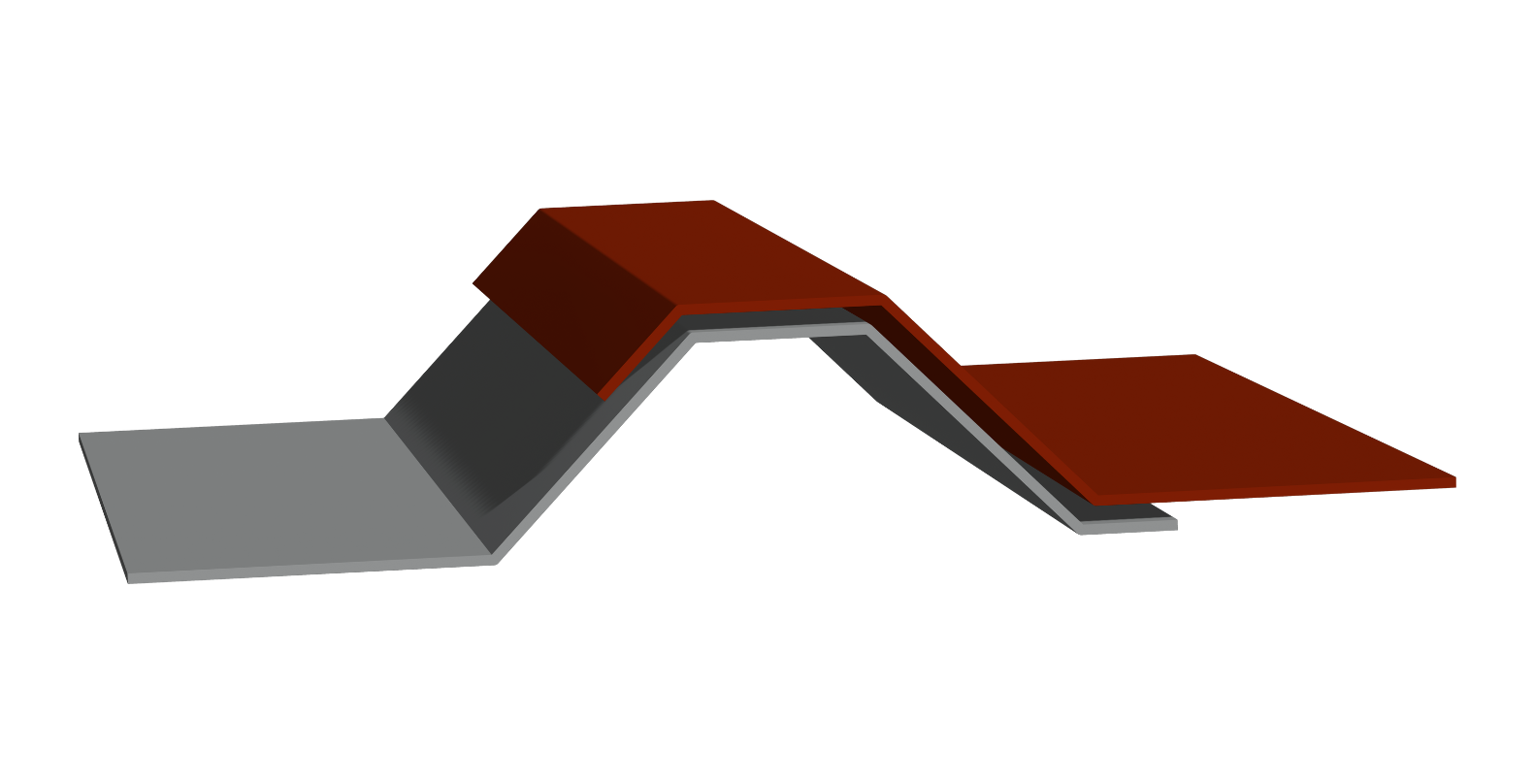

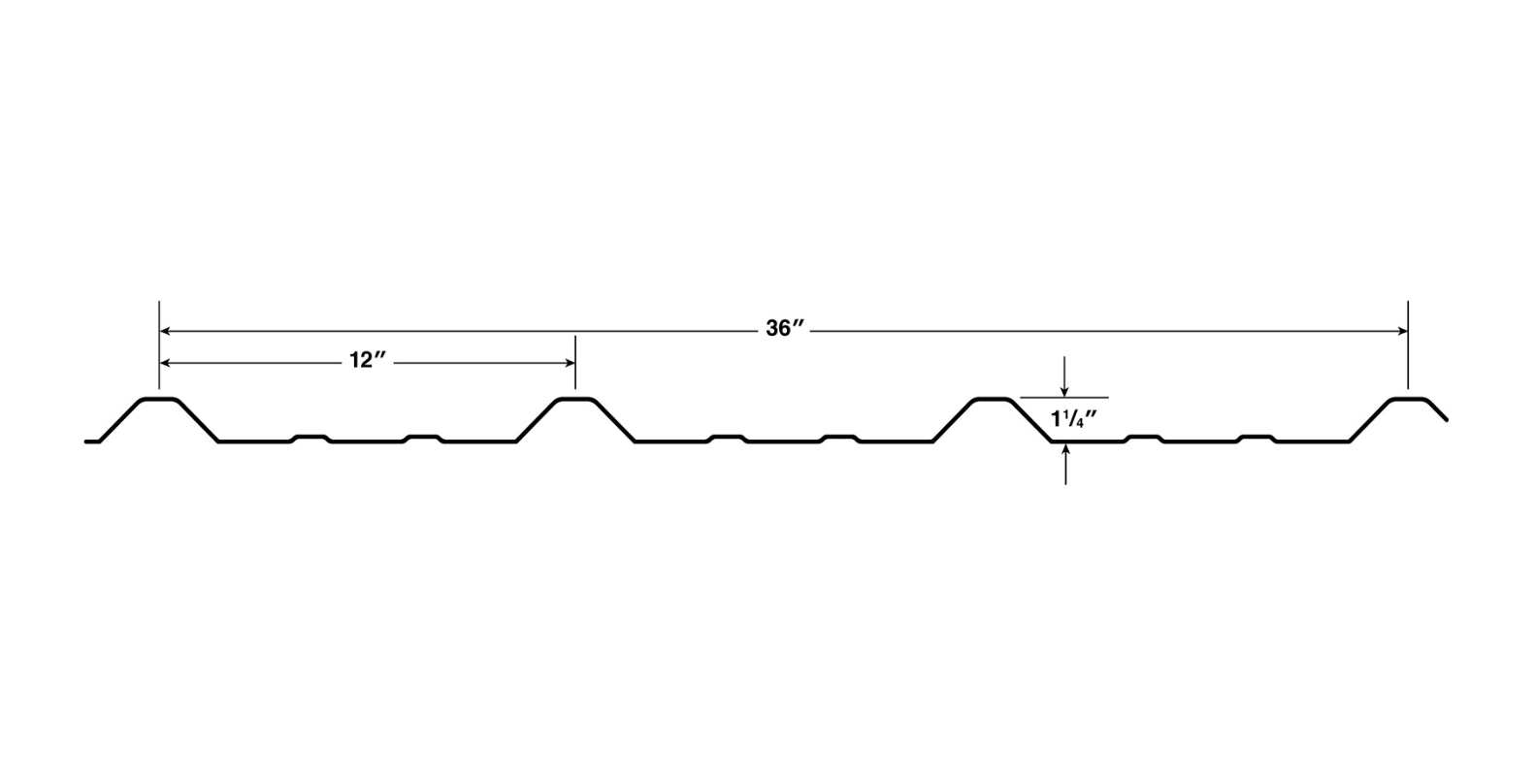

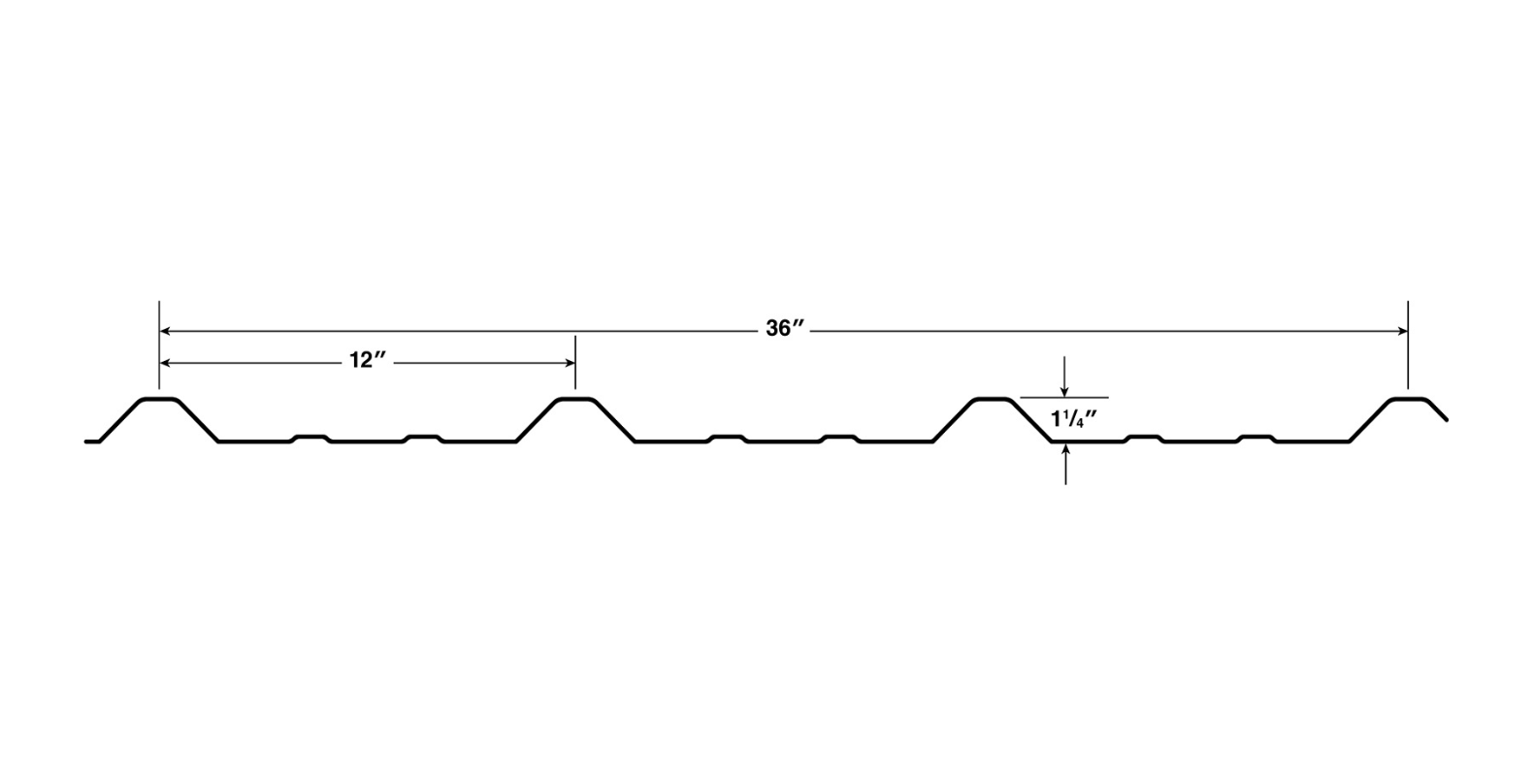

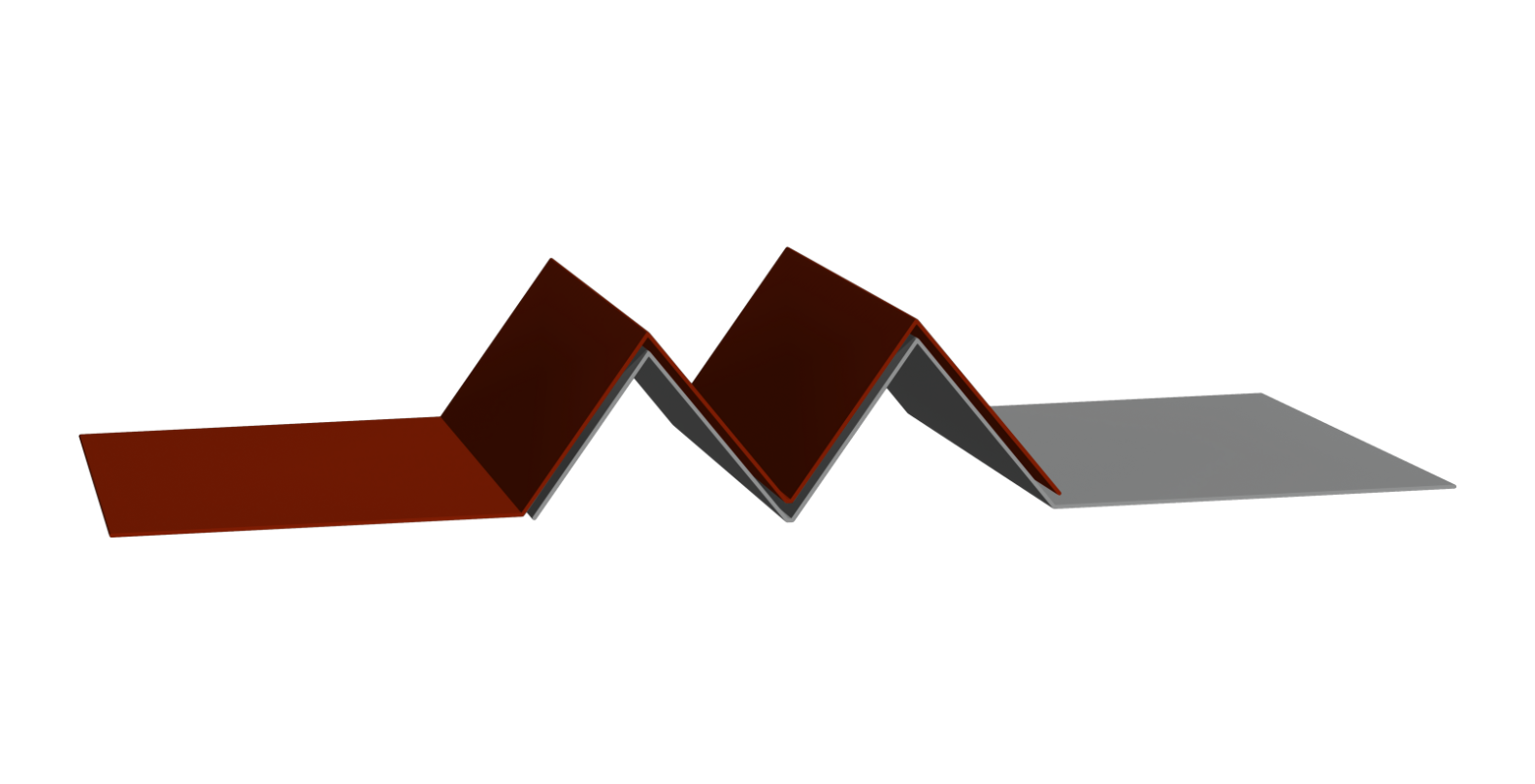

The PBR (Purlin Bearing R) Panel is a strong exposed fastener metal panel designed for commercial and industrial roofing and siding applications. With a wide 36” coverage and 1¼” rib height spaced 12” apart, it offers excellent structural support and spans easily over open framing. Its tall rib height enhances weather resistance, making it ideal for low-slope roofs. Made from Galvalume® coated steel and available in 26 and 24 gauge, the PBR Panel is finished with Sherwin-Williams WeatherXL™ for long-lasting color and protection. Choose from a wide range of colors to match your project’s style and performance needs.

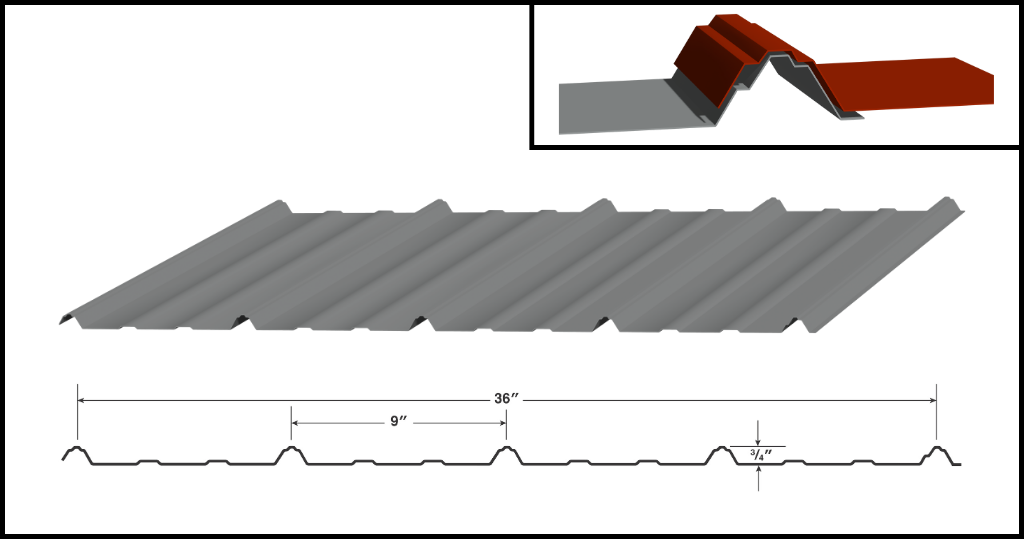

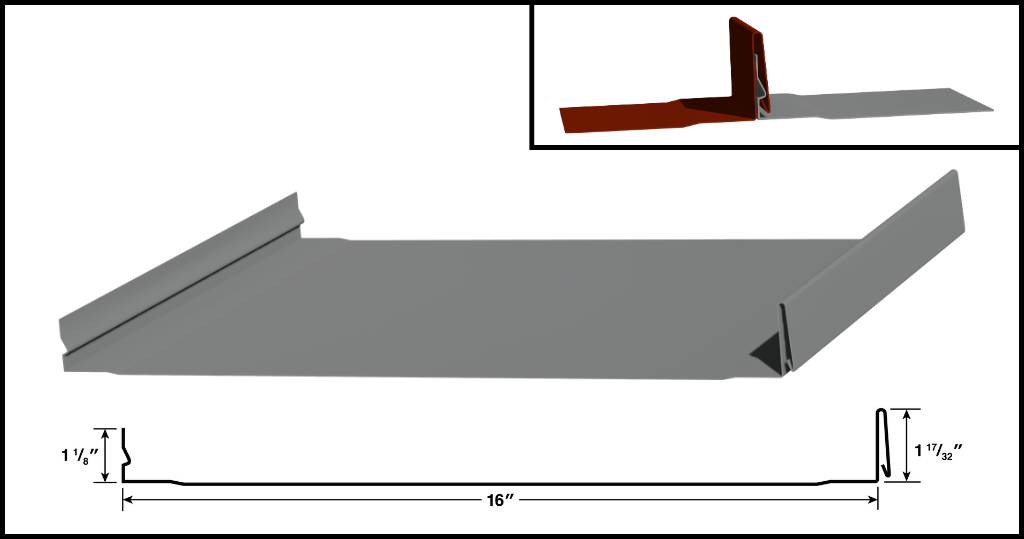

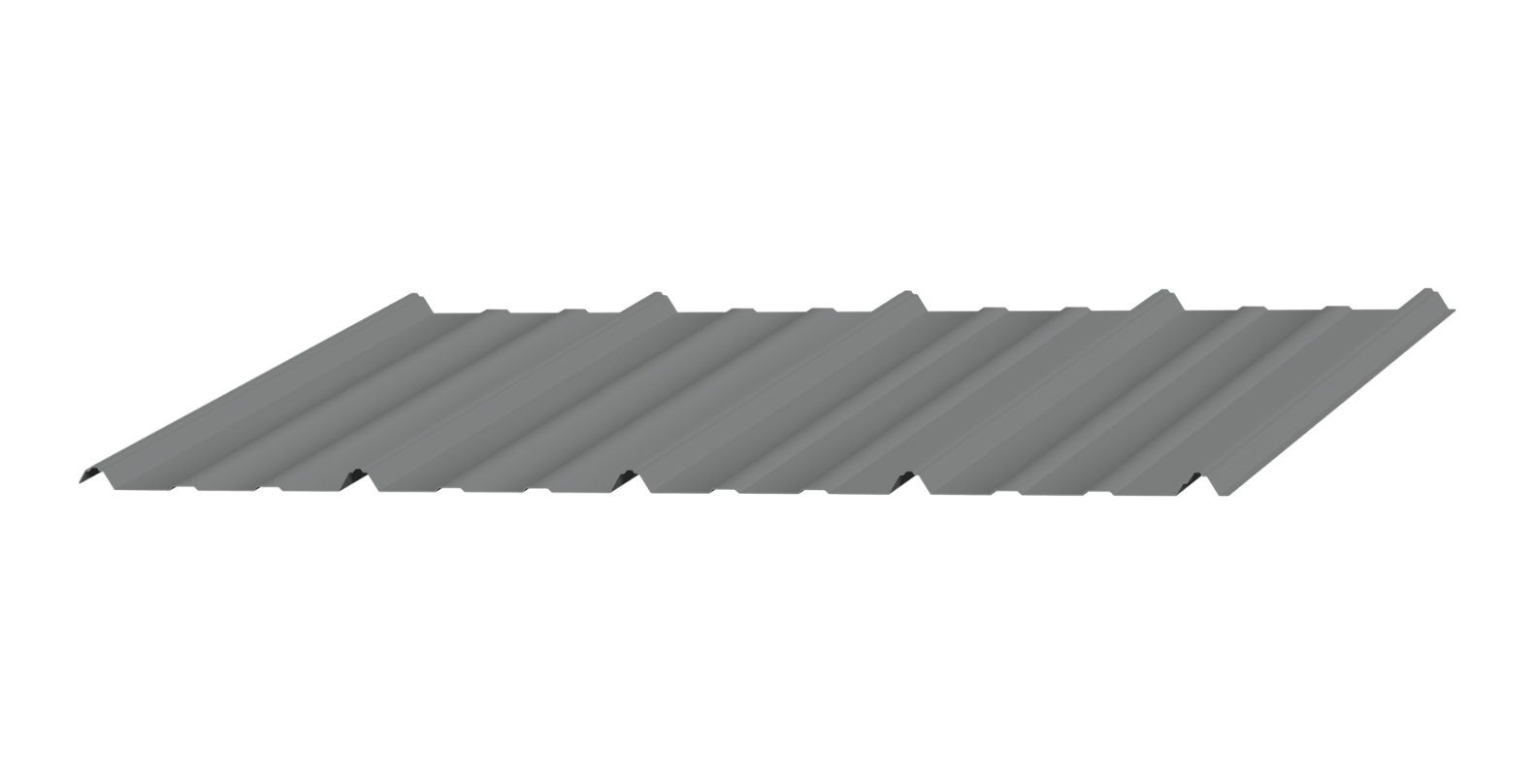

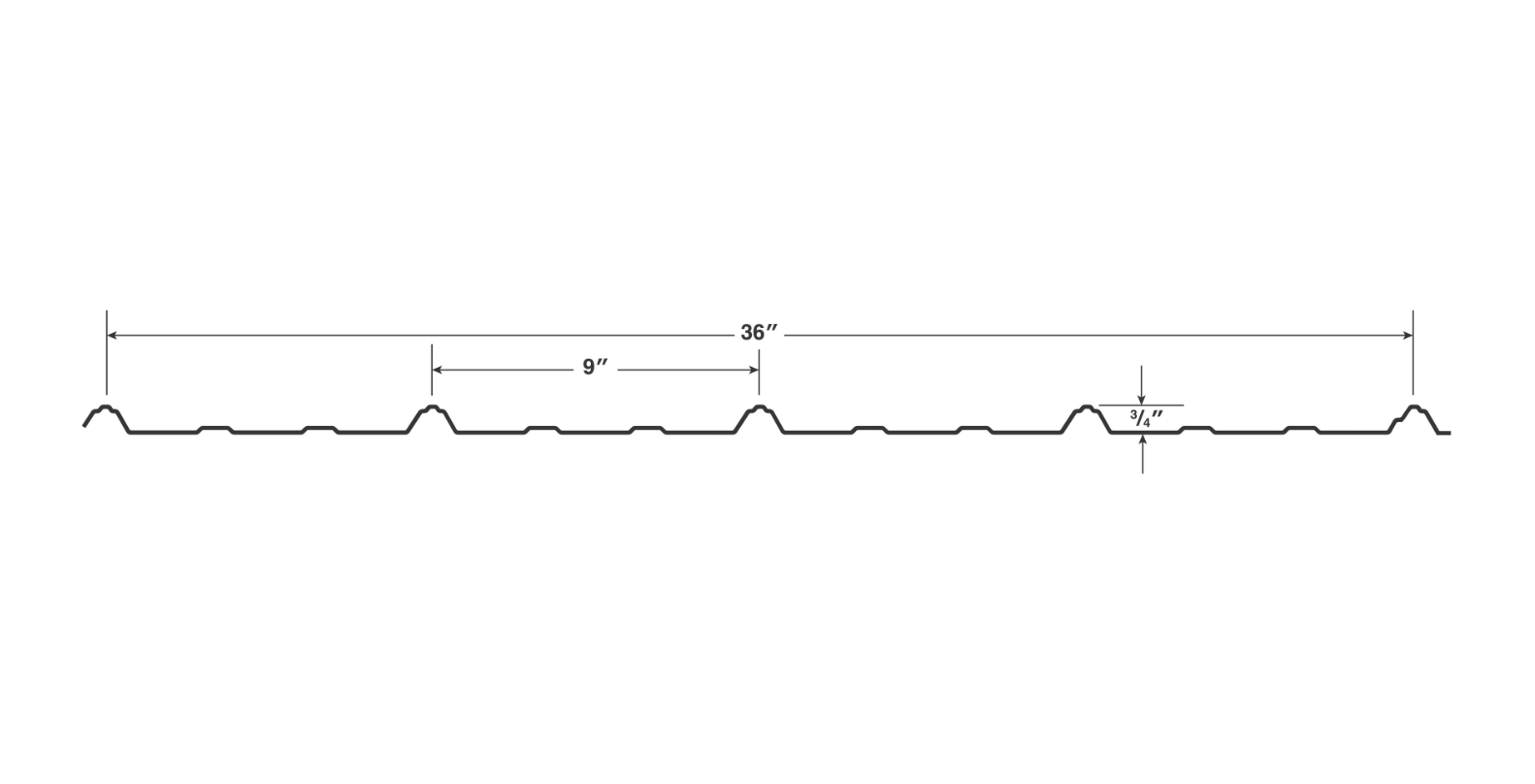

The MaxPanel™ is our most universal and budget-friendly exposed fastener panel, ideal for residential, agricultural, post-frame, and light commercial projects. With 36” coverage, ¾” rib height, and ribs spaced 9” apart, it offers a clean, traditional look with dependable performance. Available in 26 or 29 gauge Galvalume® coated steel, MaxPanel™ installs easily over open framing or solid substrates. Its screw-down design makes it a practical solution for a wide range of building types. Finished with Sherwin-Williams WeatherXL™, it’s available in a broad selection of colors to complement any structure.

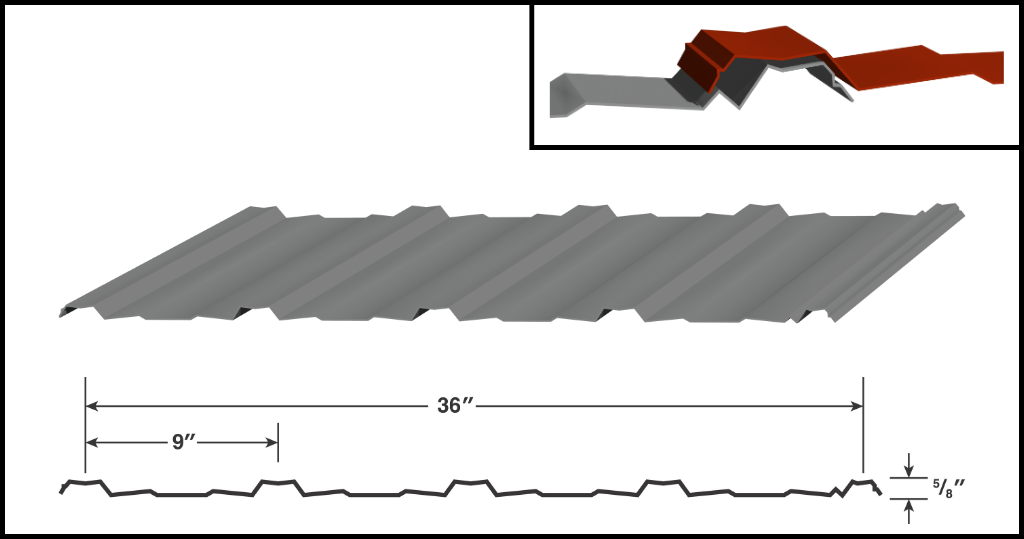

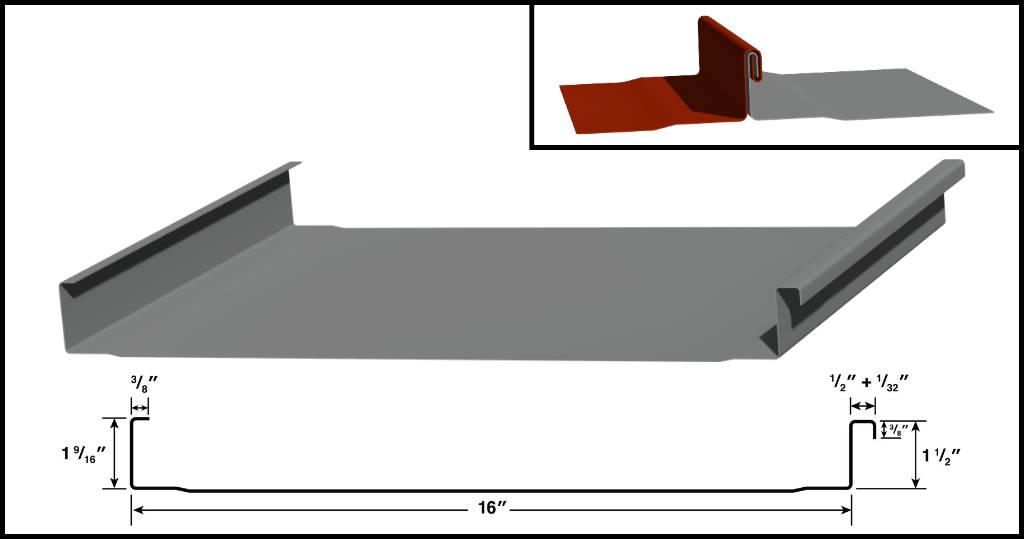

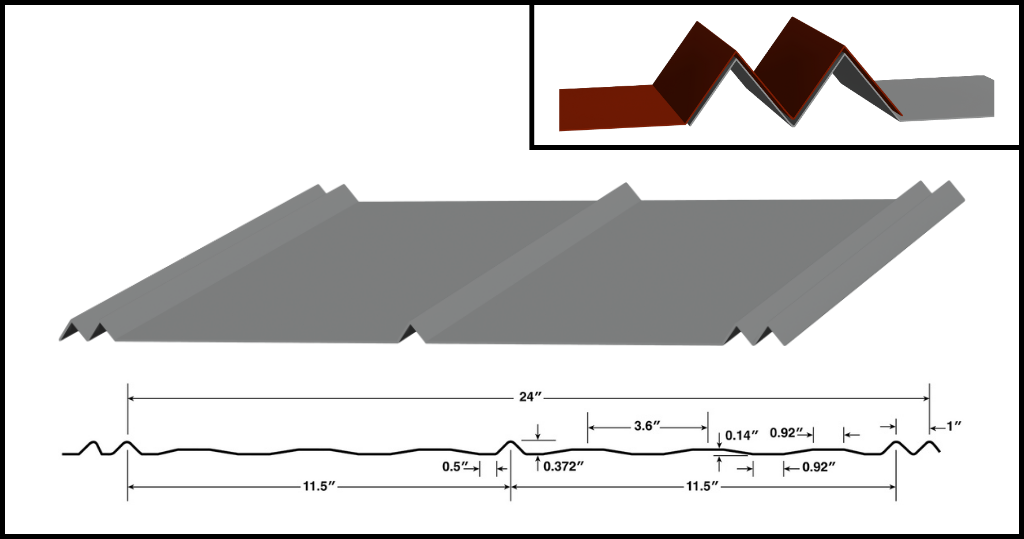

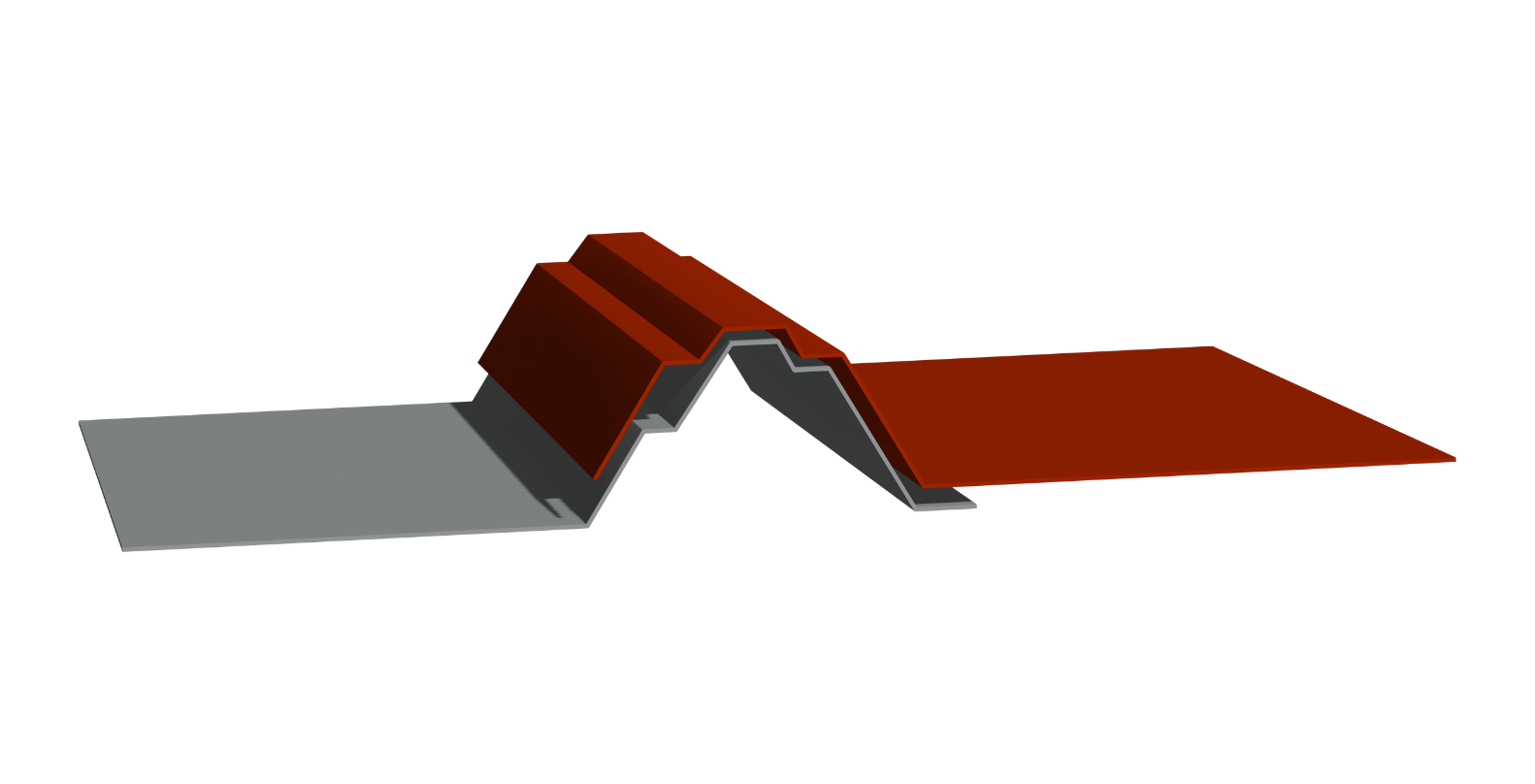

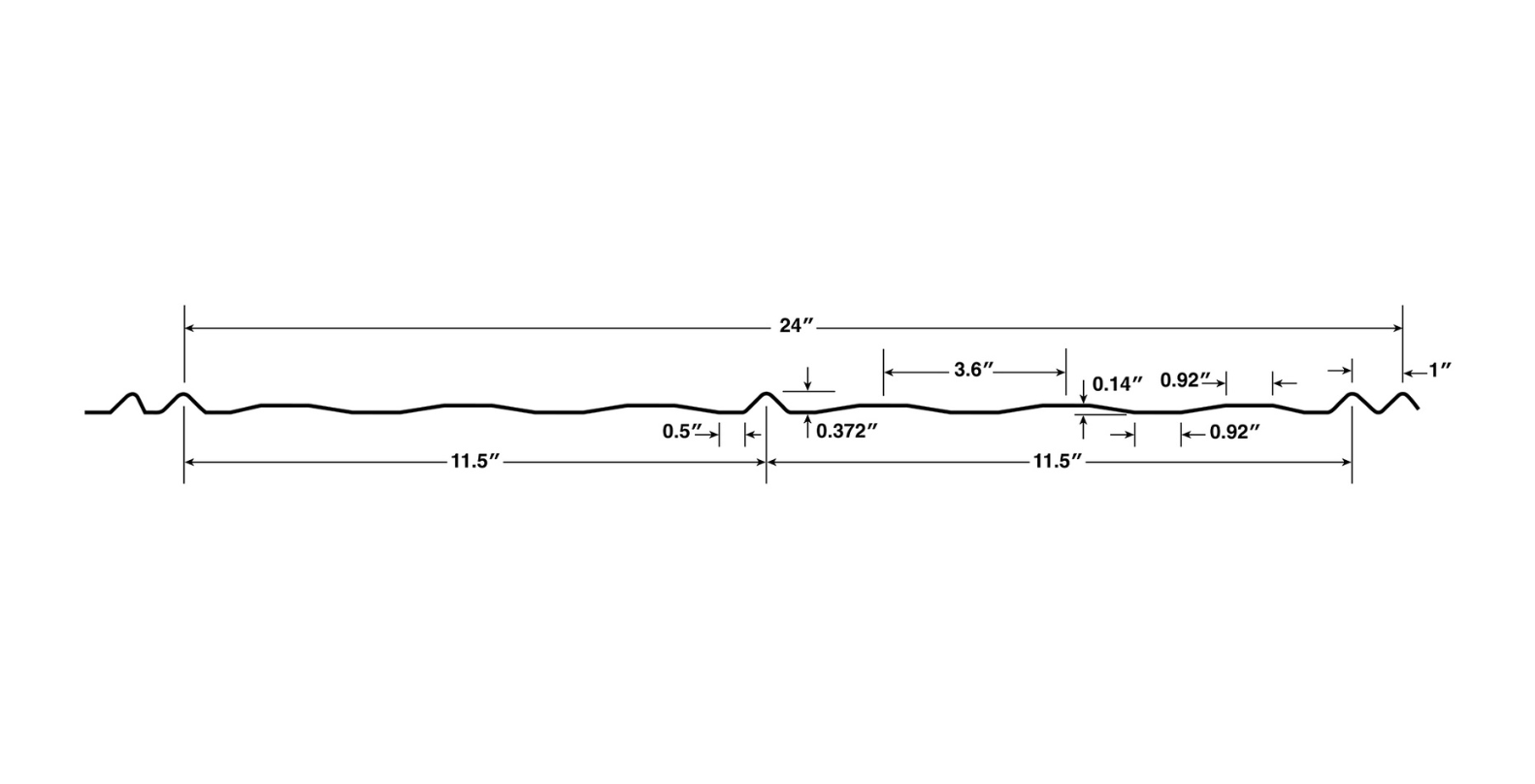

The 5V Crimp panel is a classic exposed fastener option known for its timeless style and reliable performance in demanding weather conditions. With 24” coverage and ⅜” high double inverted-V ribs, it features an anti-siphoning channel that enhances leak resistance making it ideal for agricultural buildings, coastal homes, and light commercial projects. Commonly used in Florida and other coastal regions, this panel installs over solid substrates and is available in AZ55 Galvalume® coated steel. Check with your local salesman for painted options in your region. Its traditional aesthetic and weather-tight design make it a trusted choice for both roofing and siding.

METAL ROOF

METALMAX EXPOSED FASTENER PROJECT GALLERY

Having trouble visualizing how our Exposed Fastener Panels would look on your building? Browse our exposed fastener project gallery and see how our PBR Panel, Max Panel, and 5V Panels have been used in the past.

Show More

Project Photos

WHY METALMAX?

MetalMax is a leading manufacturer of high-quality metal building components and solutions with locations in Tennessee, Texas, New Hampshire, Georgia, Florida, Oregon, Ohio, Iowa, and Alabama. We provide metal panels, trim, red iron, underlayment, screws, tools, sliding doors, accessories, and building systems for residential, agricultural, and commercial building needs. Our operations continue to grow as we meet the needs of our customers locally and nationally.

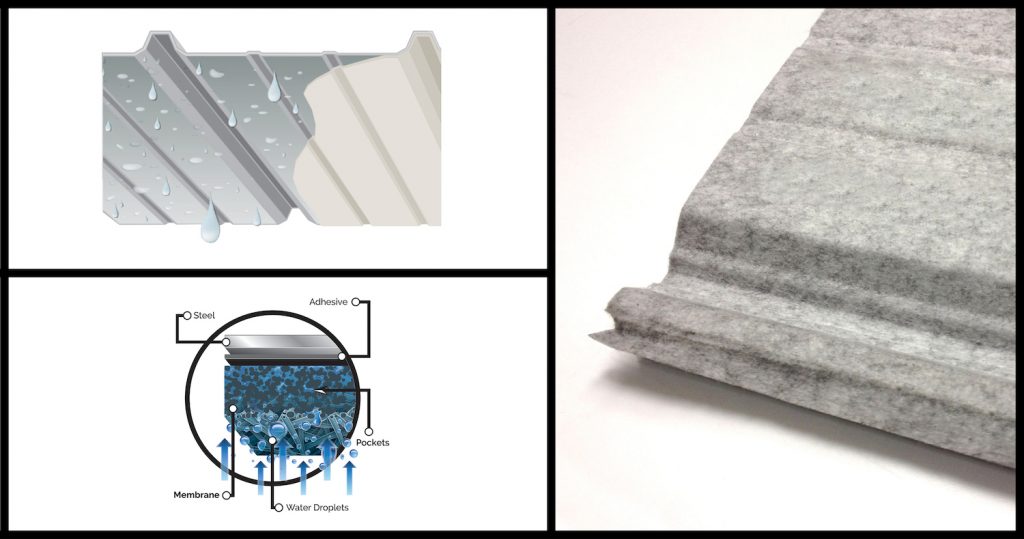

We use Galvalume® coated steel panels, which protect the panel from rust using layers of metal and polymer coatings to maintain corrosion resistance. All are backed by our industry leading Limited Lifetime Paint Warranty.

Builders know that no two structures are exactly the same, so we’re here to make the one-off custom trim shapes needed to finish any job to perfection.

We manufacture in 12 locations nationwide and offer a Limited Lifetime Paint Warranty on our WeatherXL coatings, backed by Sherwin Williams.

There is no need to stress about logistics. Our services offer delivery to safely bring the materials needed to the job site, so you don’t have to.

We guarantee quality products that meet our customer’s expectations. Our staff is helpful and considerate to all metal roofing needs, big and small.

With 12 locations in the U.S., we manufacture AND can deliver using our own trucks, ensuring you’ll get the products you need…WHEN you need them.

ARE YOU A CONTRACTOR OR A BARN BUILDER?

If you’re a roofing contractor, a building contractor, or a portable building or barn company, we’ve got what you need. Our Exposed Fastener Panels are cost-effective and come with an industry-leading warranty. Fill out the form below and one of our team members will be in touch with you regarding your project!

NOT YOUR NEAREST METALMAX LOCATION? WE’VE GOT OTHERS.

If you are considering metal roofing, siding, or have a building project, MetalMax is here to help. We are a knowledgeable manufacturer in both metal roofing as well as building materials and systems. We have locations across the United States and we’re still growing.

Just click on the location nearest you on the map below to reveal the address, phone number and driving directions for that location.