COLD-FORMED STEEL BUILDINGS

Cold-formed steel boasts exceptional strength, making it a viable option for constructing robust, long-lasting buildings. A cold-formed steel building (or CFSB), is a type of construction method that utilizes steel sheets or strips that are formed at room temperature to create various structural components. These components can include studs, joists, purlins, and other framing elements. Cold-formed steel is distinguished from hot-rolled steel, which is shaped at higher temperatures.

Cold-formed steel buildings offer a range of benefits, making them a popular choice in modern construction. They are used for a variety of purposes, from residential housing to commercial and industrial facilities. The have become an extremely popular option for customers looking to build Barn-dominiums!

In the realm of modern construction, innovation and sustainability have become paramount. Cold-formed steel buildings, are a product of this evolution and stand as a testament to the engineering prowess of the 21st century. These structures offer a variety of advantages, ranging from cost-effectiveness to environmental sustainability.

- Commercial Buildings

- Industrial Buildings

- BARN-dominiums

- Small and Large Barns

- Home Workshops

- Residential Garages

COLD-FORMED STEEL ADVANTAGES

Lead Times

Conventional metal buildings are notorious for long lead times that stretch into several months due to the fabrication process. Cold Formed Steel Buildings are constructed entirely with roll-formed components, which are more efficient to ship and eliminate the need to pre-fabricate and weld frames in a plant. The end-result is lower lead times!

For Customers AND Contractors…time is money! Cold Formed Steel Buildings have precisely manufactured components that assemble easily on site without the need for welding. Installation crews can complete jobs quickly compared to same-sized buildings made from red iron. That means YOUR building is up and ready for use MUCH faster!

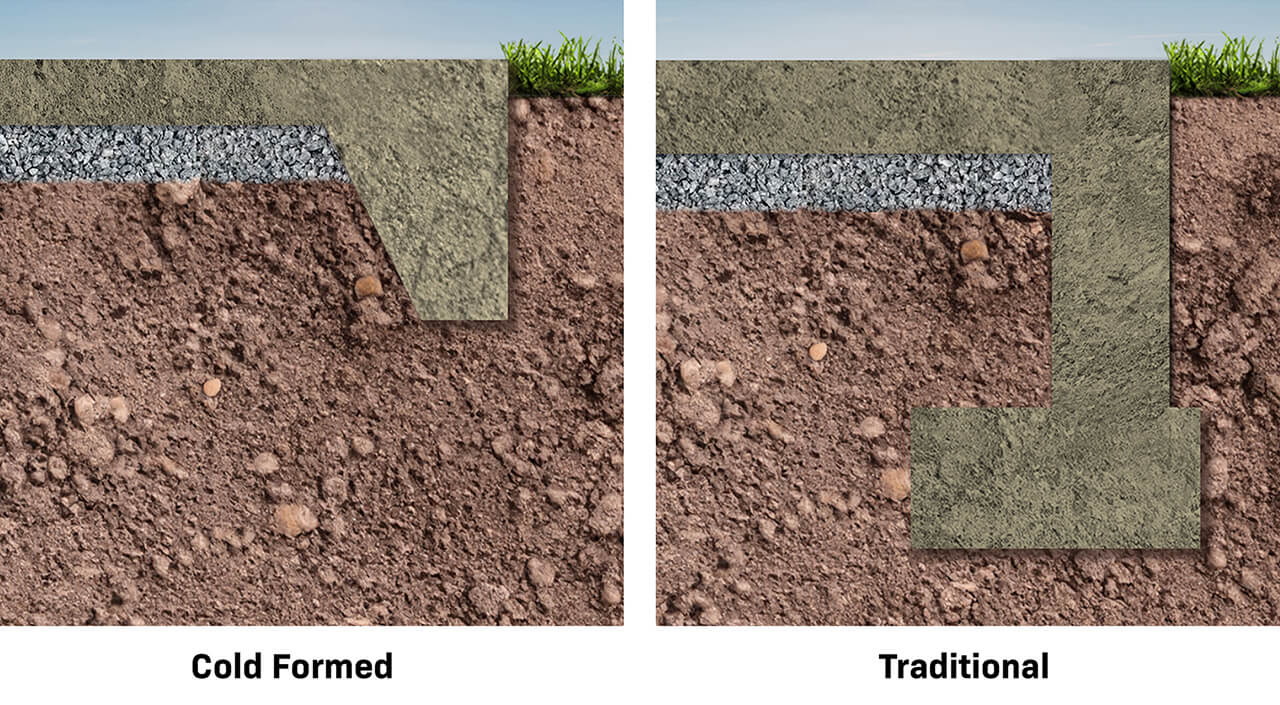

Cold Formed Steel Buildings spread the loads over multiple frame lines, resulting in smaller loads at each column. Compared to other structures, concrete foundations for Cold Formed Steel Buildings can be simpler and are often accomplished with a single pour. This results in a more efficient foundation design in both labor and material, which saves money.

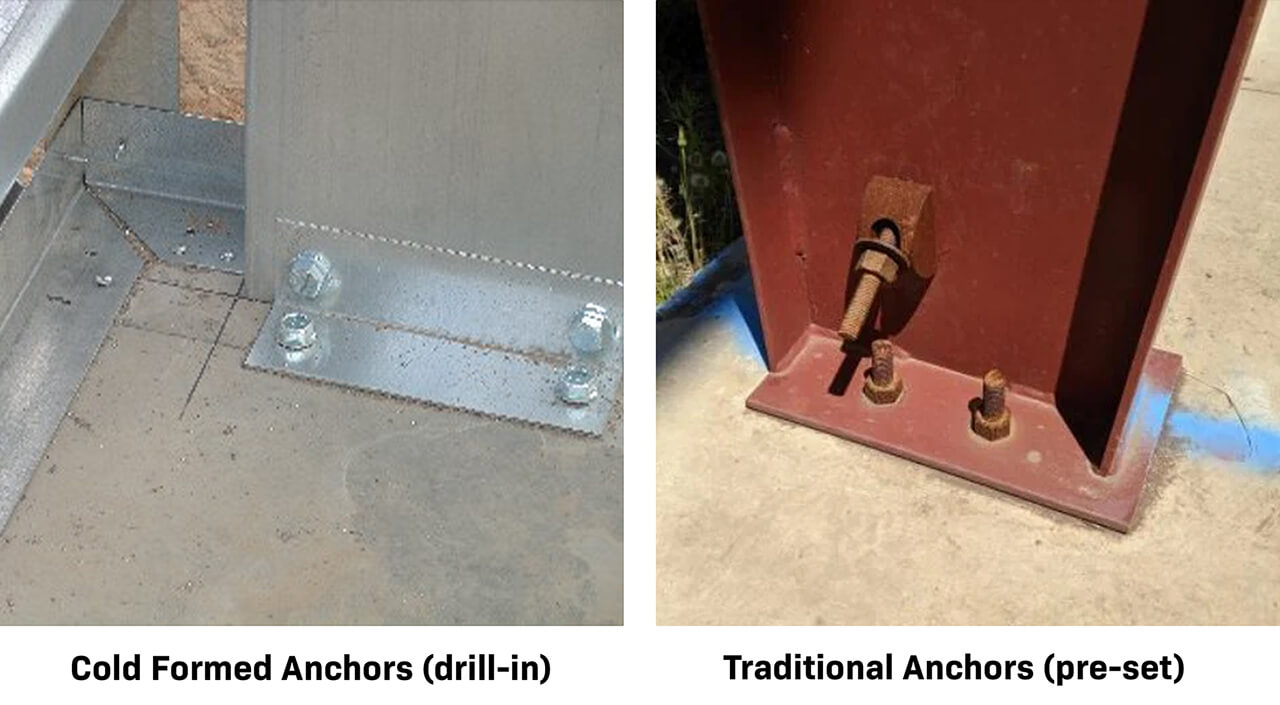

Cold Formed Steel Buildings are anchored to the foundation using post-installed anchors that are drilled into the slab during installation. Unlike traditional buildings, they don’t require pre-set anchor bolts to accommodate the columns. This takes some guesswork out of the anchoring process and speeds up installation!

Cold Formed Steel Buildings are manufactured with precise roll-formed and weld-free components, greatly reducing the need for on-site notching a fabrication. Every pre-fabricated building kit comes with accurate engineer drawings and instructions. Depending on the size and complexity, it’s not uncommon for customers to DIY their building installation.

Traditional red iron frames have visible weld seams and blemishes. The red coating is there to protect the raw steel and camouflage corrosion, but looks ugly…making it unsuitable for exposed frame interiors. Cold Formed Steel Buildings are manufactured from Galvanized material, offering a clean appearance AND protection against corrosion.

COLD-FORMED STEEL BUILDING PACKAGES

MetalMax offers a variety of pre-configured building packages at highly competitive prices…any of which can be configured using the customer’s choice of panel color and profile. They are all fully customizable based on the customer’s needs. MetalMax also offers building components for contractors who simply need a reliable and economical source to purchase from.

Perfect for a home workshop, this space combines indoor and outdoor functionality. Open the garage doors to move items in or provide natural light and stay protected under its front lean to.

30' x 50' x 12'

1,500

Charcoal Gray Roof

Polar White Trim

(1) 4'x4' Window

(2) 10'x12' Roll-up Doors

Prices vary based on local building codes, material costs & project management requirements.

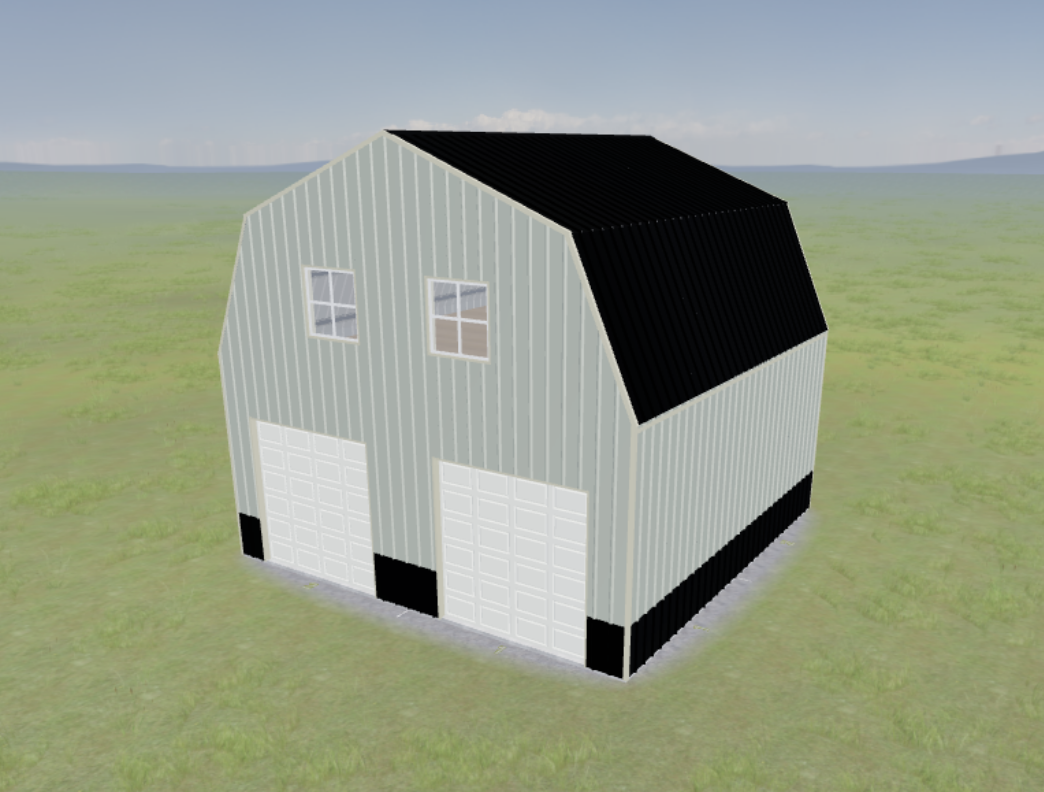

This gambrel roof barn provides the look of a traditional agricultural barn with modern engineering. Its high ceilings and garage doors provide extra storage for a variety of items.

30' x 30' x 14'

900

Black Roof

Ivory Trim

(4) 10'x10' Roll-up Doors

Prices vary based on local building codes, material costs & project management requirements.

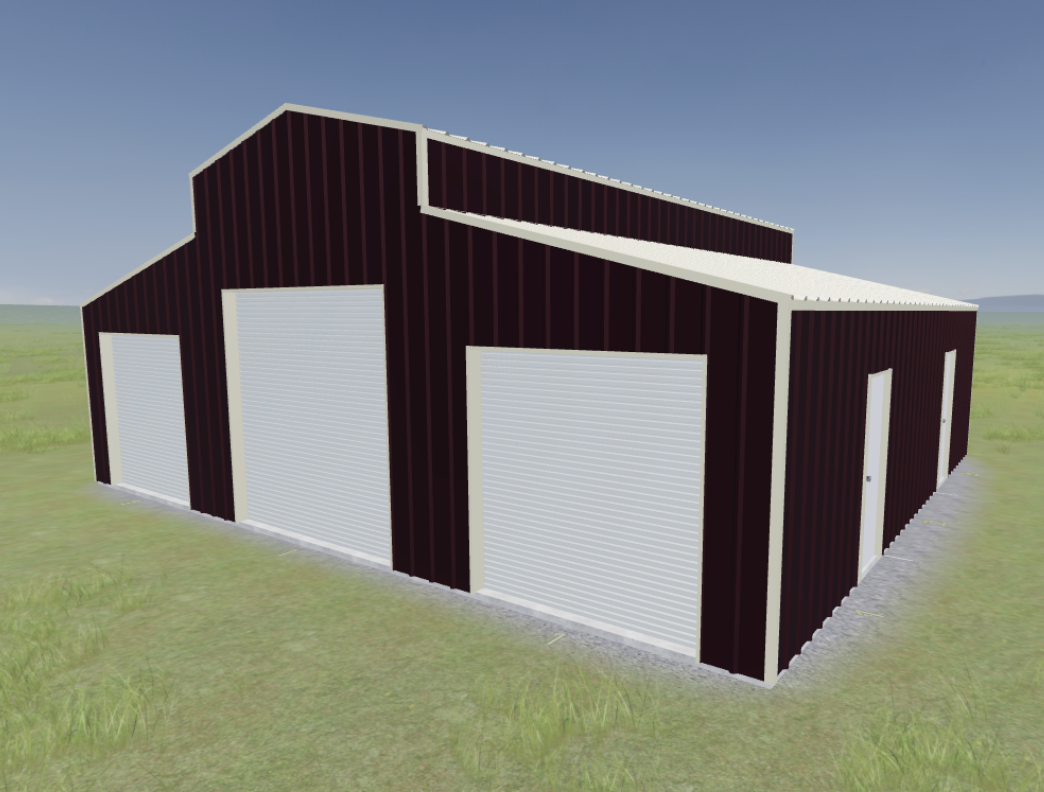

Characterized by its raised center section and lower side wings, this monitor style barn combines function and aesthetics. Use it for anything from agricultural applications to event spaces.

40' x 30' x 14'

1,200

Ivory Roof

Ivory Trim

(2) 8'x8' Roll-up Doors

(1) 10'x10' Roll-up Door

(2) Lean-to's

Prices vary based on local building codes, material costs & project management requirements.

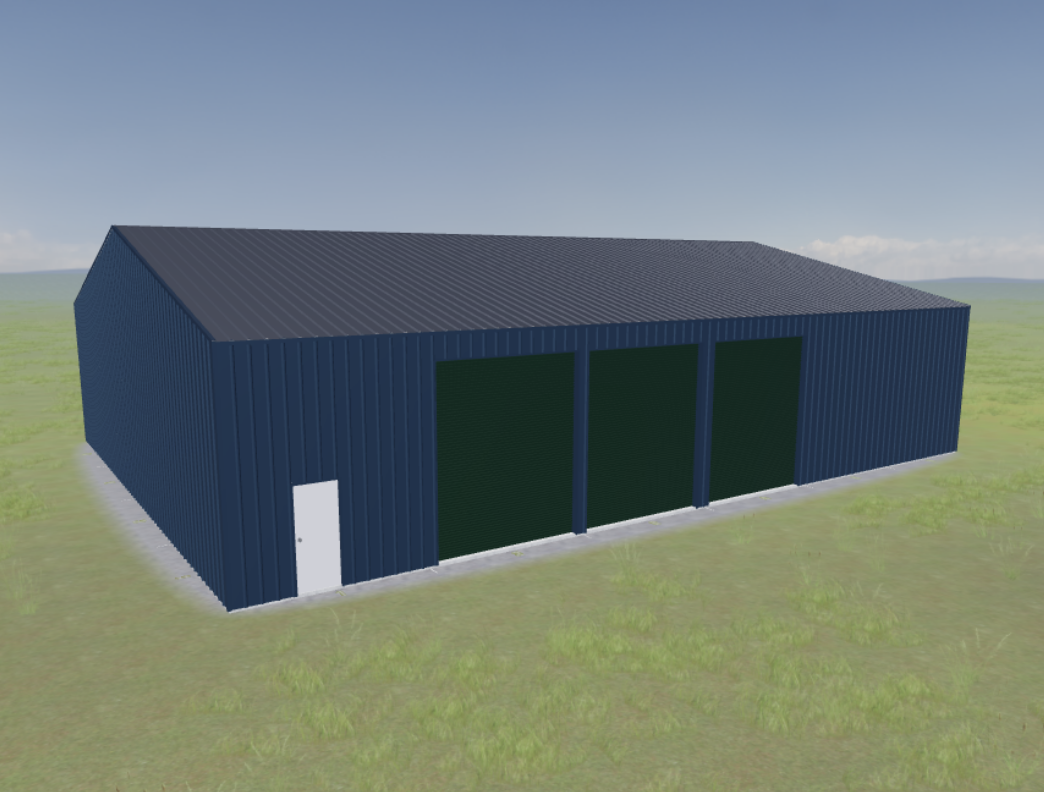

This large-scale equipment barn is the ultimate storage solution. At over 4,800 square feet, this building is a versatile playground for anything you can imagine.

60' x 80' x 16'

4,800

Hawaiian Blue Trim

Charcoal Gray Roof

(3) 12'x14' Roll-up Doors

Prices vary based on local building codes, material costs & project management requirements.

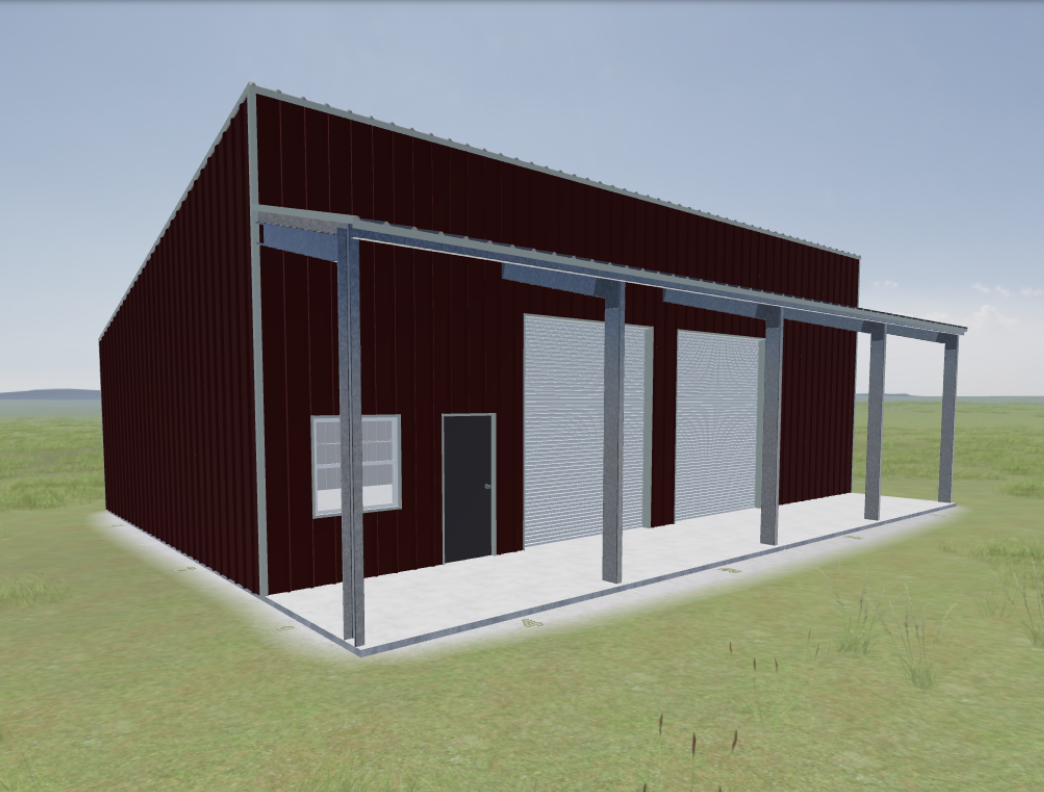

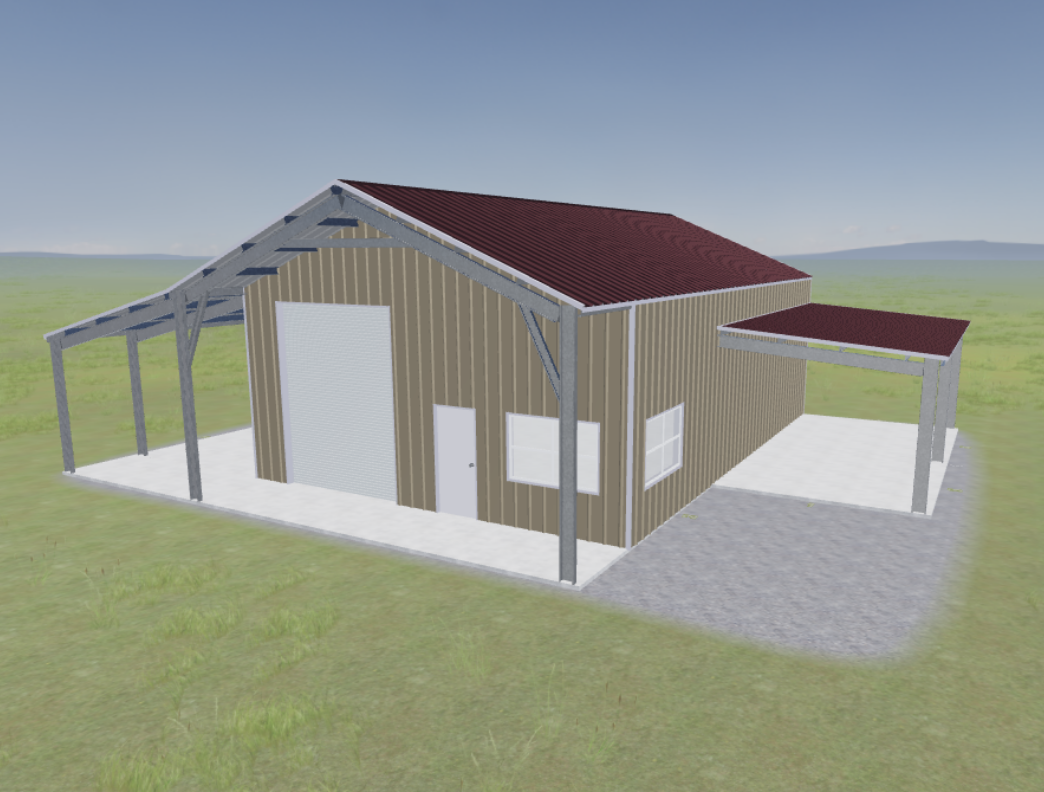

With its multiple overhangs and large garage door, this barn is a versatile space to store a variety of large and small items. Its windows allow plenty of natural light for comfortable indoor use as well.

30’ x 50’ x 14’

1,500

Burgundy Roof

Arctic White Trim

(4) 6’x4’ Windows

(1) 10’x13’ Roll-up Doors

Lean-Tos & Overhangs

Prices vary based on local building codes, material costs & project management requirements.

COMMON QUESTIONS ABOUT COLD-FORMED STEEL

WHAT IS A COLD-FORMED BUILDING?

A cold-formed metal building is assembled from roll-formed, galvanized steel members that are factory-punched and cut for precise, lightweight framing using bolted connections.

WHAT MAKES COLD-FORMED DIFFERENT FROM TRADITIONAL STEEL?

Cold formed steel is shaped at room temperature, making it lighter, more flexible, more cost-effective, and easier to install than hot-rolled structural steel.

HOW ARE THE COMPONENTS MANUFACTURED AND ASSEMBLED?

Components are roll-formed from steel coils, pre-punched, and bolted or screwed together on-site like a large, precise metal kit.

CAN COLD-FORMED BUILDINGS SUPPORT CLEAR SPAN INTERIOR LAYOUTS?

Yes, cold formed buildings can achieve wide clear spans using engineered trusses and framing systems without interior support columns.

WHAT KIND OF FOUNDATION IS NEEDED FOR A COLD FORMED BUILDING?

Typically, a concrete slab or pier foundation is used, depending on building size, soil conditions, and local codes.

COLD-FORMED STEEL BUILDING PROJECT GALLERY

Having trouble visualizing the possibilities with our Cold Formed Steel building system? Or do you just want to see how it all comes together on a job site? Check out the installation video below as well as the example project gallery to see what the possibilities are.

Show More

Project Photos

COLD-FORMED STEEL ROOFING & SIDING PANEL & COLOR OPTIONS

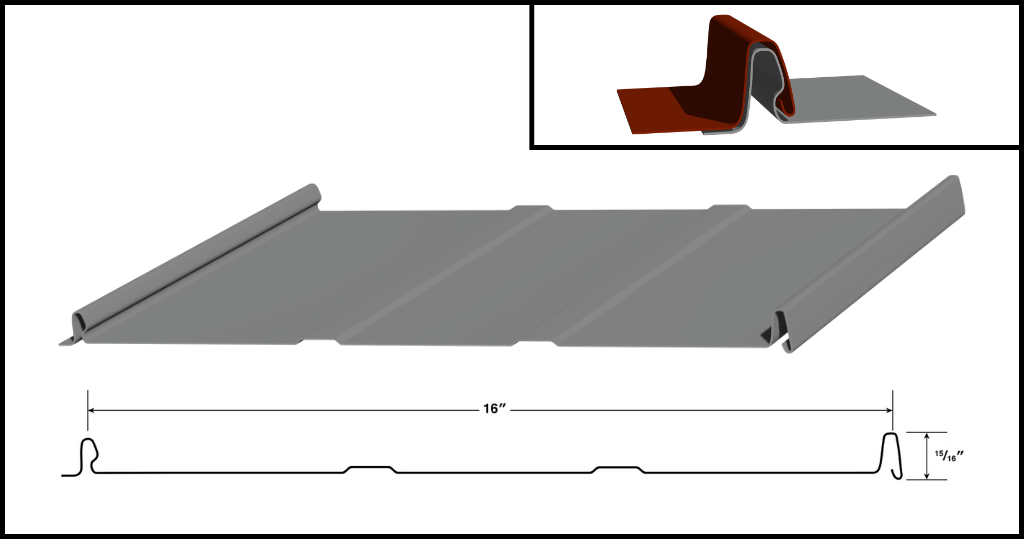

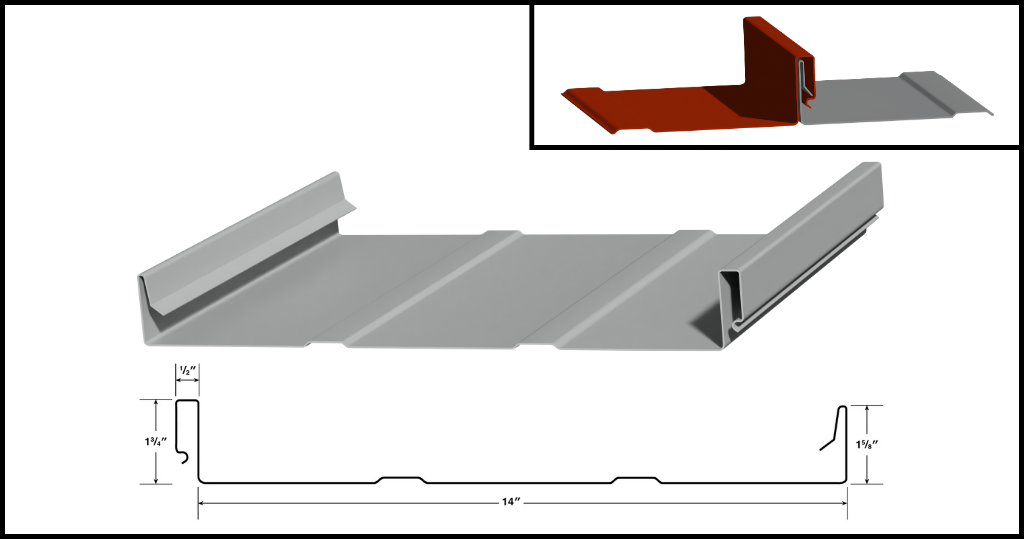

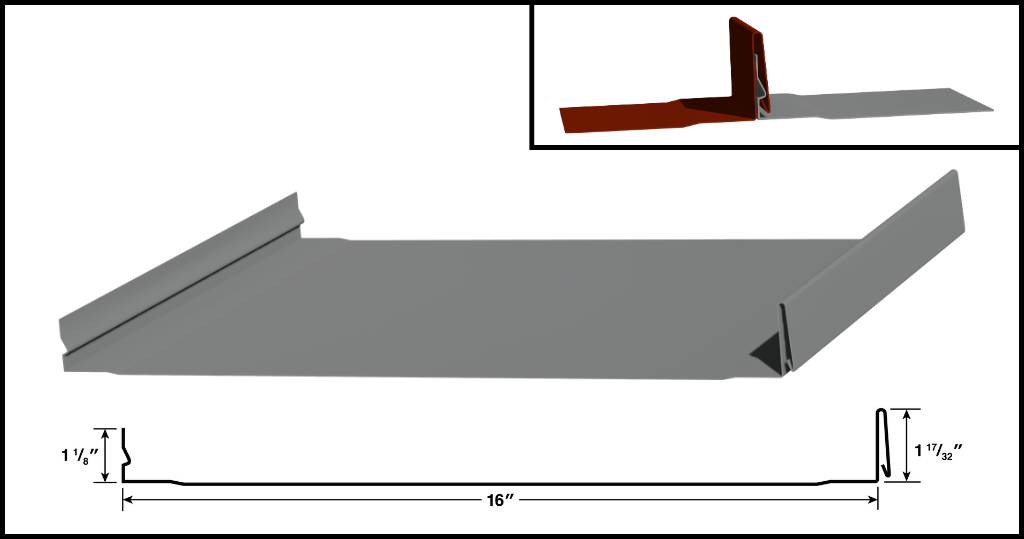

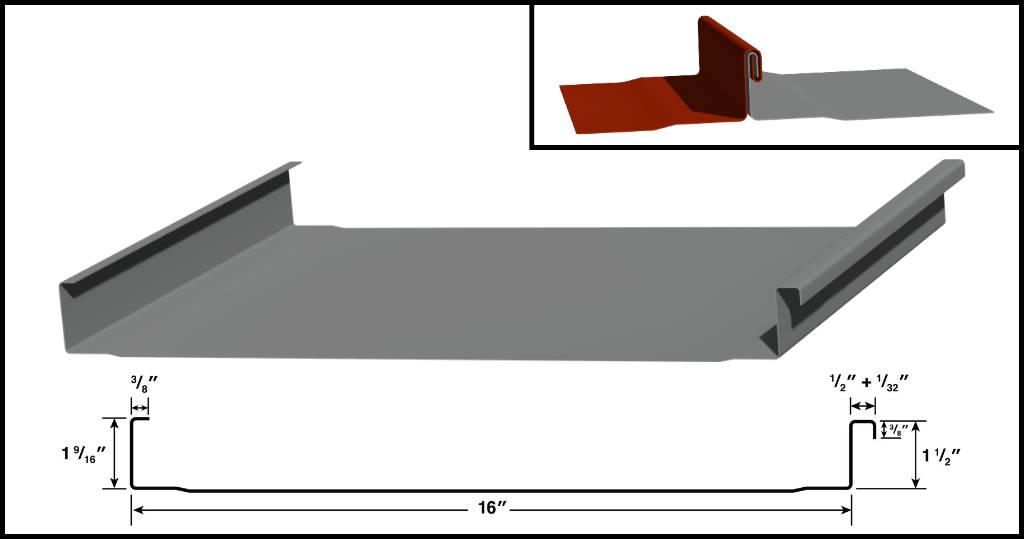

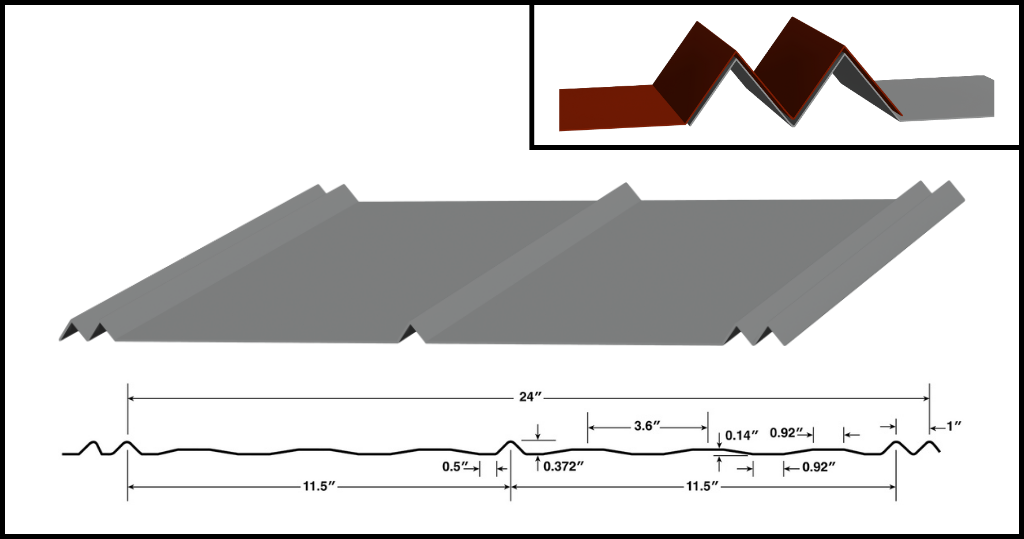

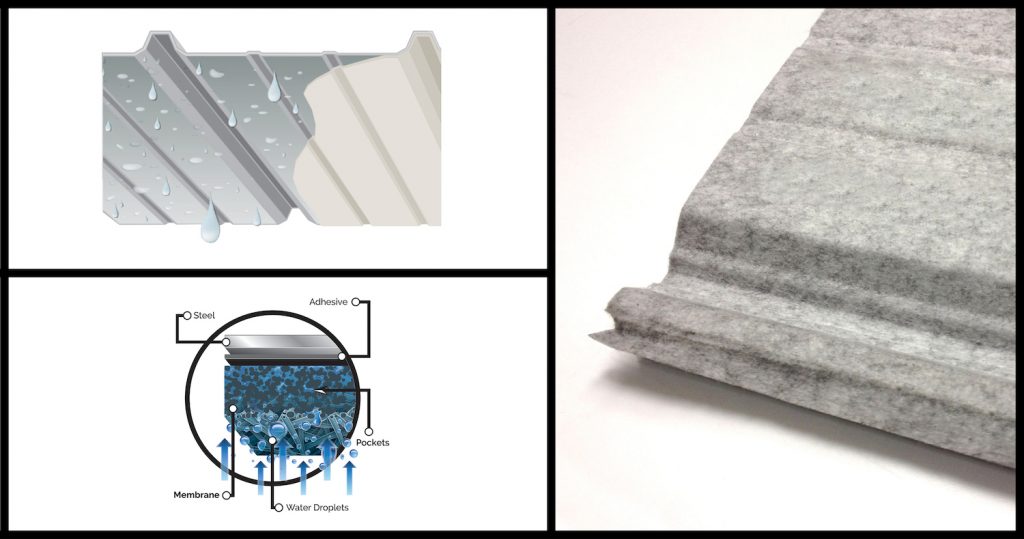

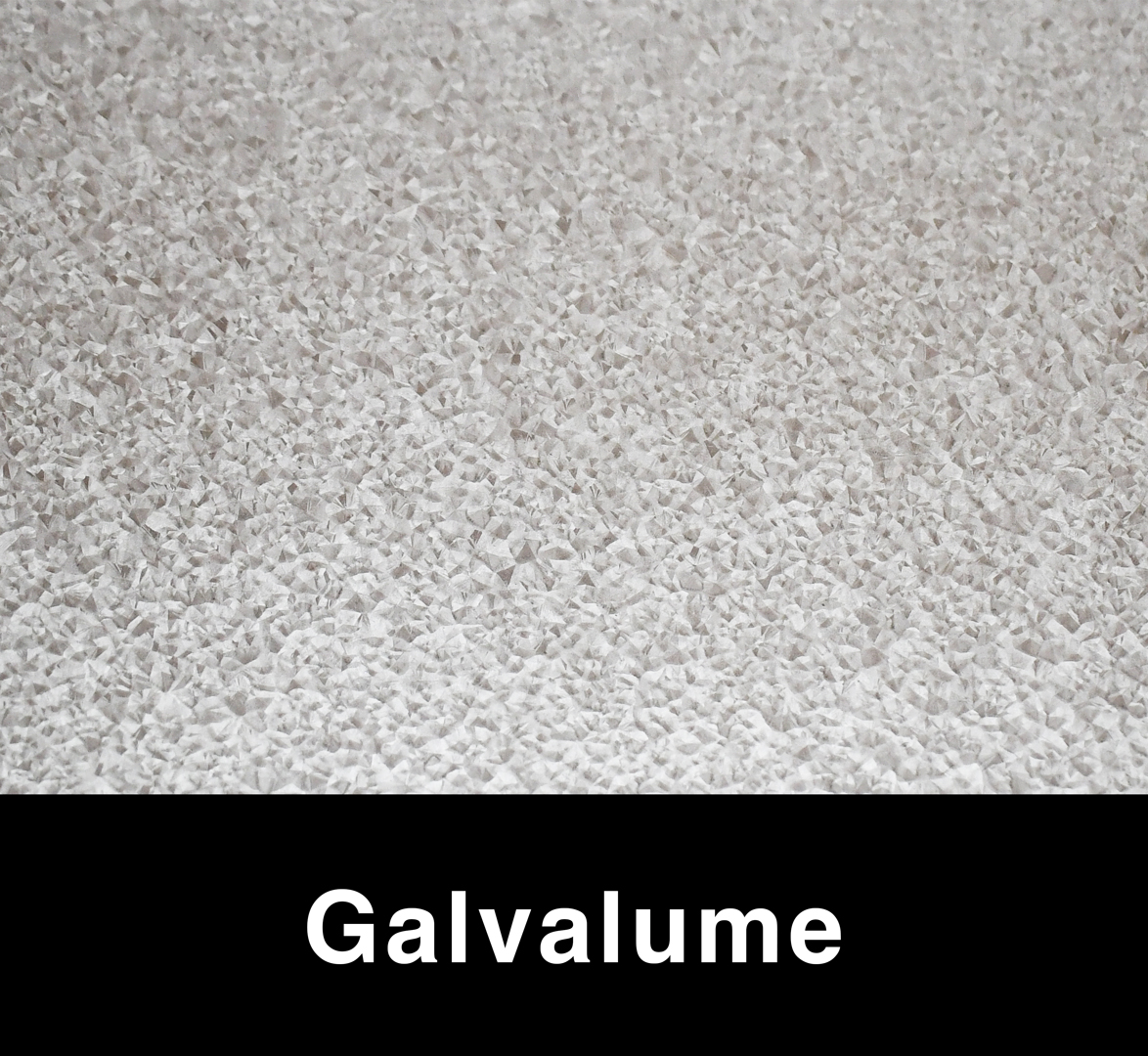

MetalMax Building Systems offers the below roofing and siding options for Cold-Formed Steel Buildings. Although PBR (Purlin Bearing Rib) and PBU (Purlin Bearing Underside) will be the most common and economical options, other panel profiles may be available in your area. Availability of alternative panel profiles, gauges and colors may vary by locations, so please contact your nearest MetalMax location for additional details.

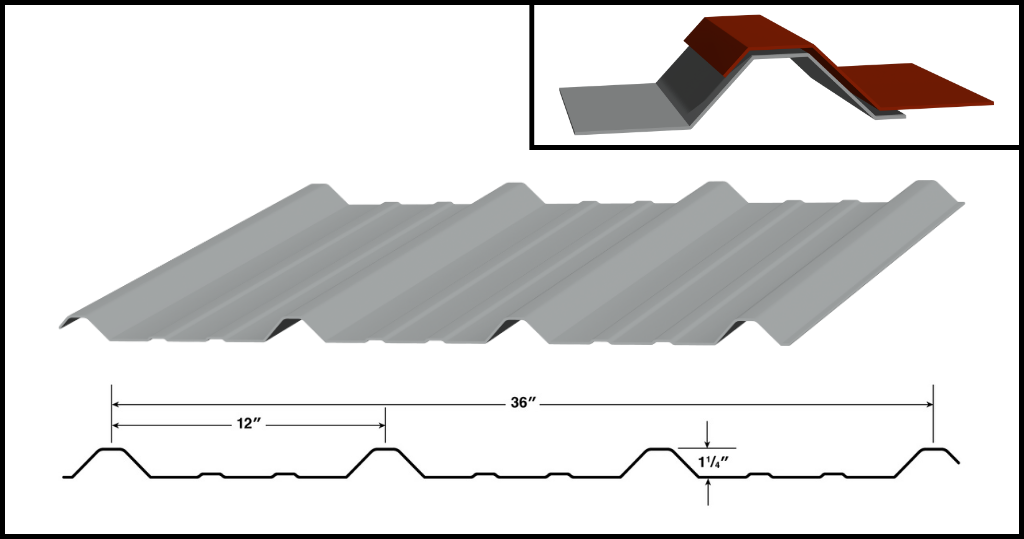

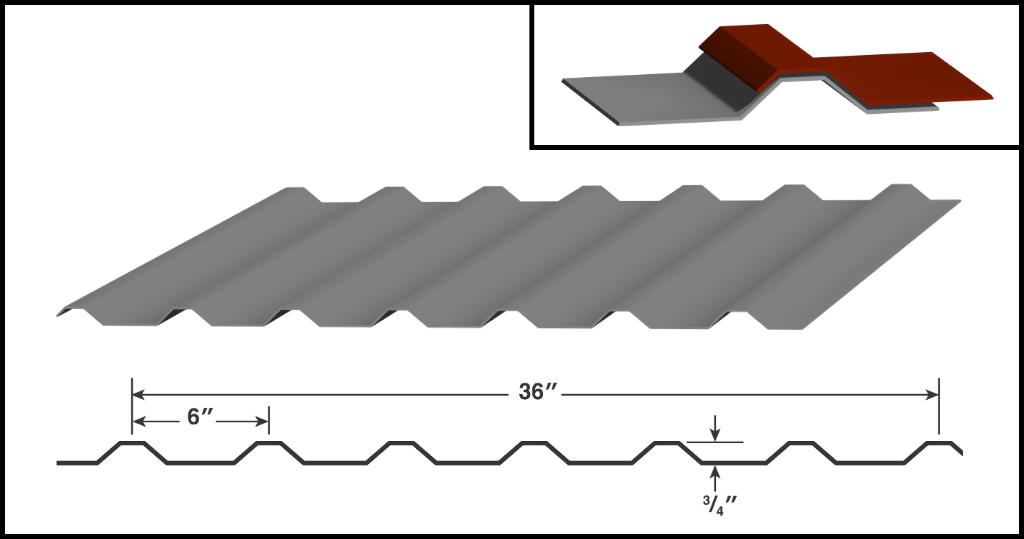

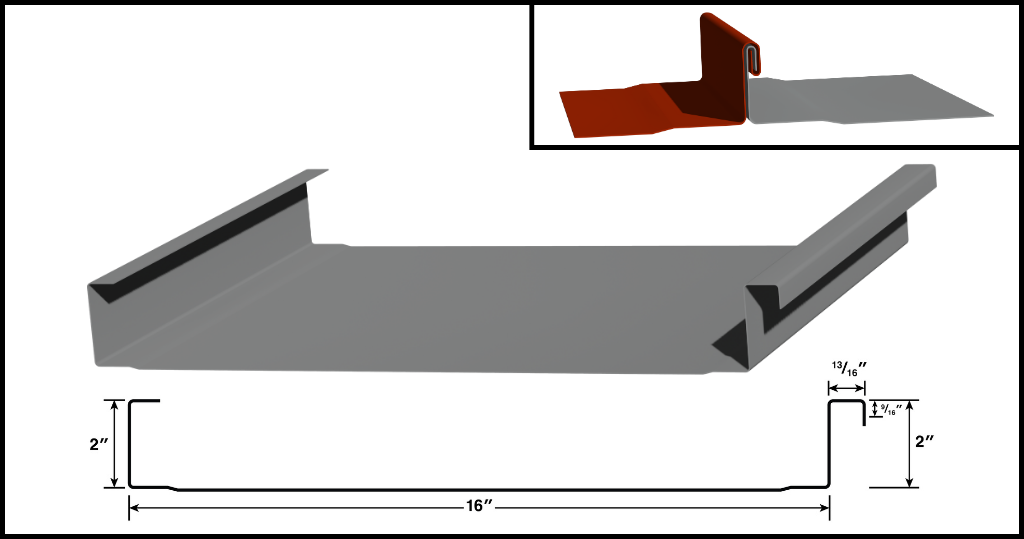

A PBU panel is a 26 gauge metal roofing and siding panel with an exposed fastener system that can be installed horizontally or vertically on roofs and walls. The “PBU” stands for “Purlin Bearing Underside,” indicating the panel’s design to bear against the purlin or substrate with a special leg on one side to aid in consistent alignment and fastening. They are a versatile and durable option for various commercial, agricultural, and industrial applications.

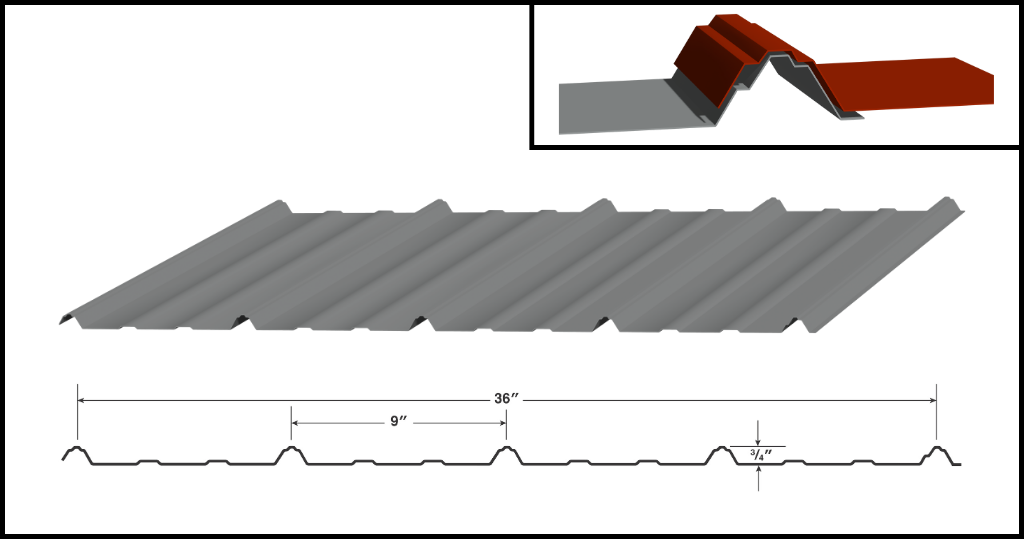

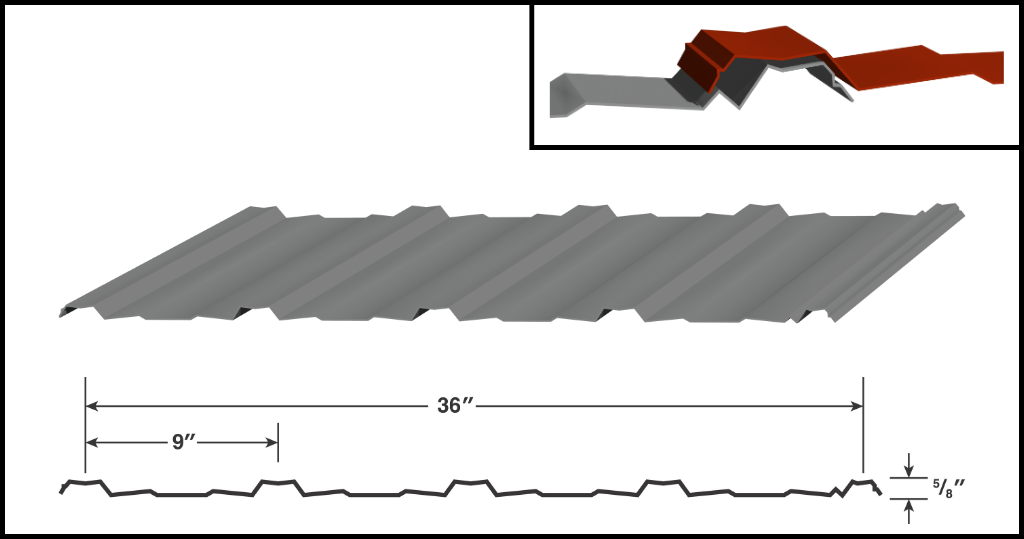

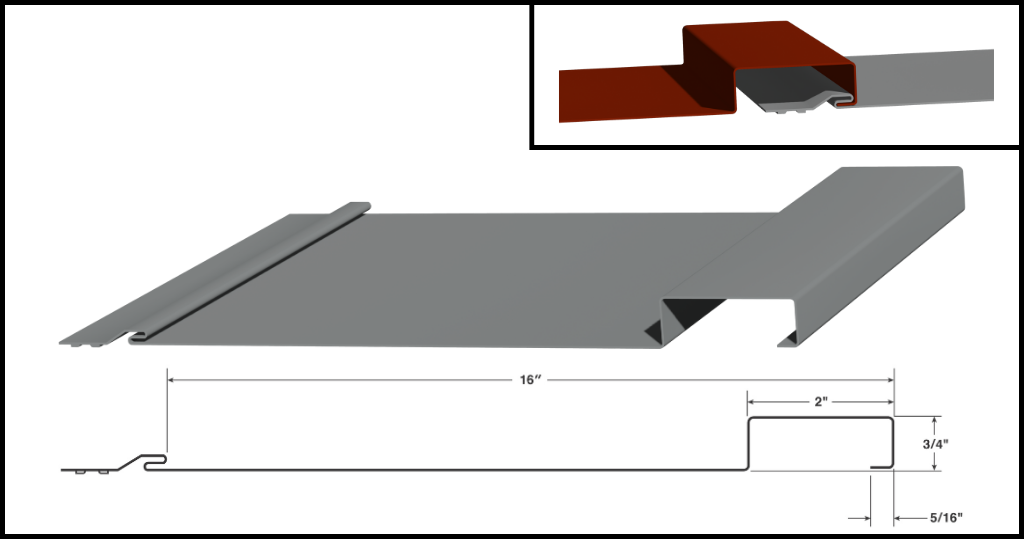

A PBR panel is a 26 gauge metal roofing and siding panel with an exposed fastener system designed for strength and weather resistance. The “PBR” stands for “Purlin Bearing Rib,” referring to the flange on the male end that supports the panel rib when fastening panels together. PBR panels are a durable, cost-effective choice for low-slope commercial, agricultural, and industrial roofing applications.

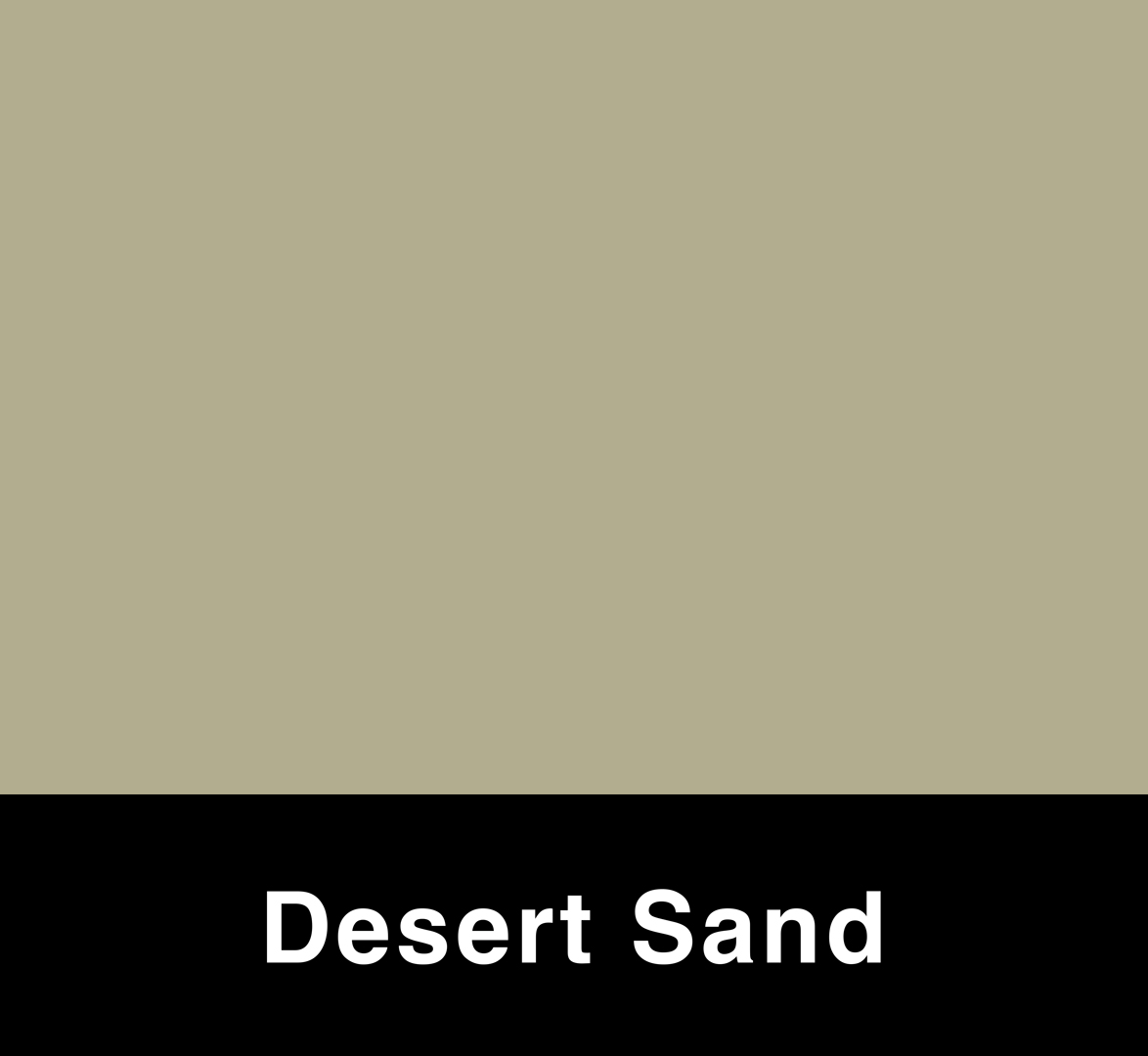

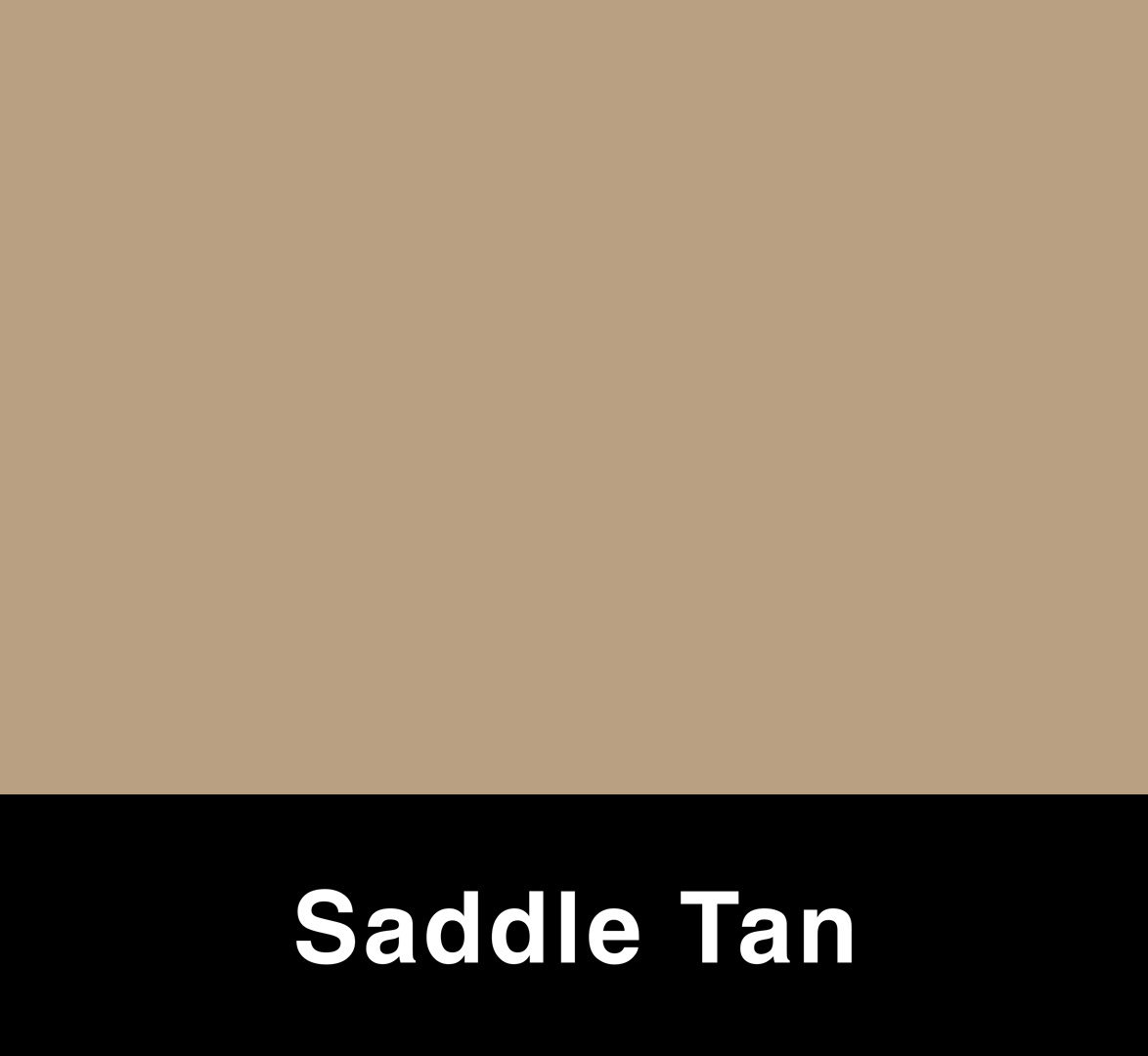

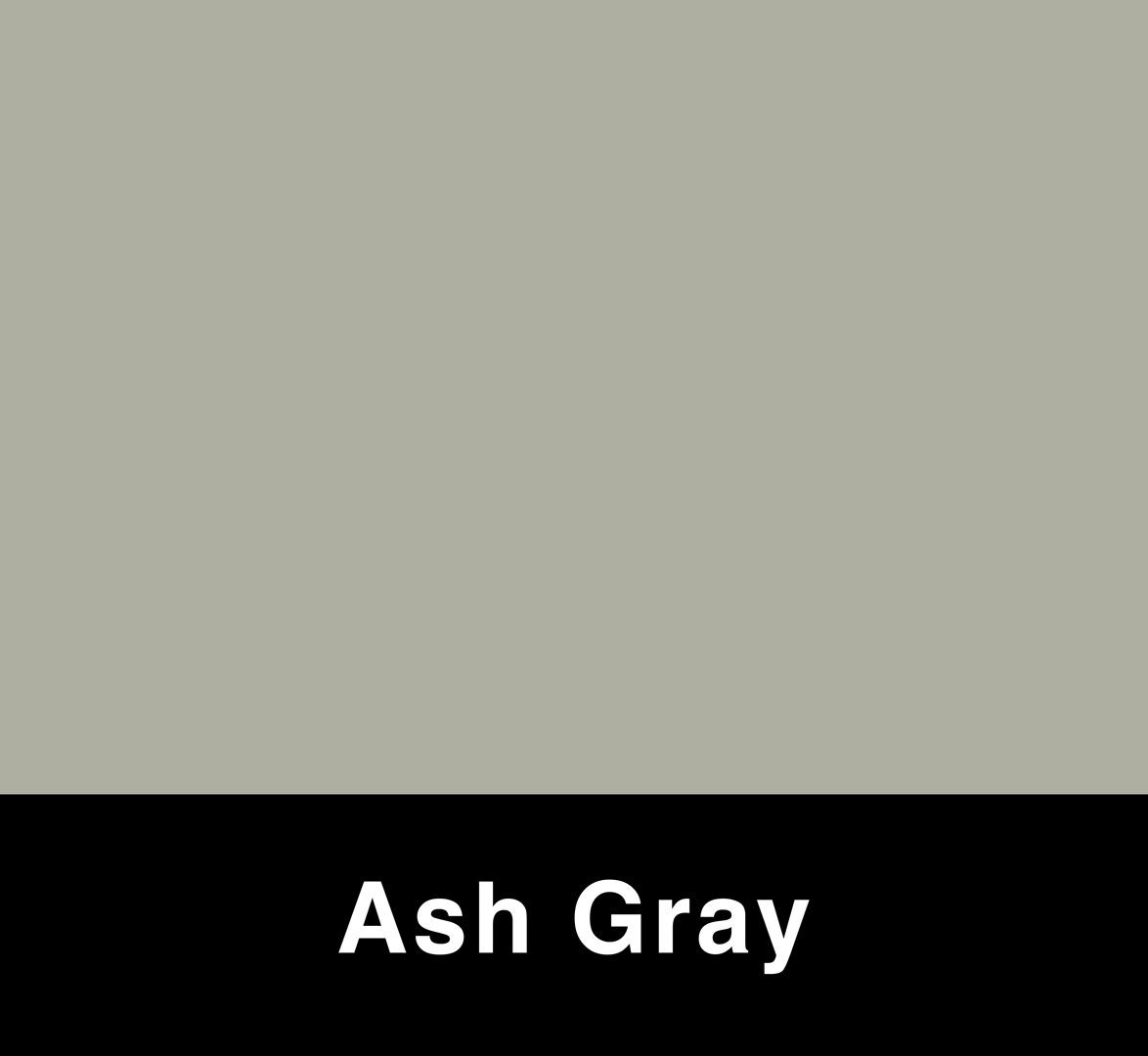

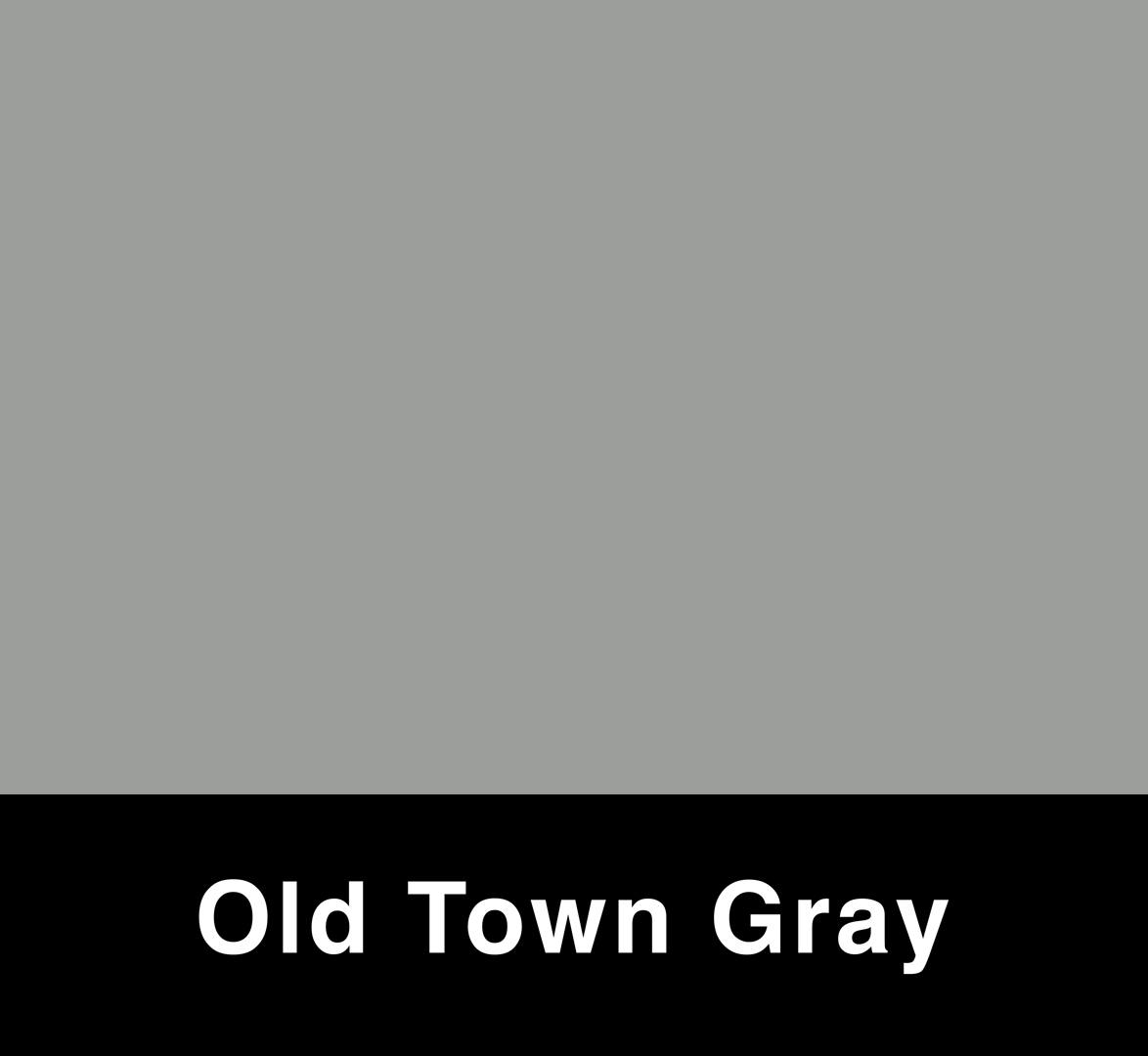

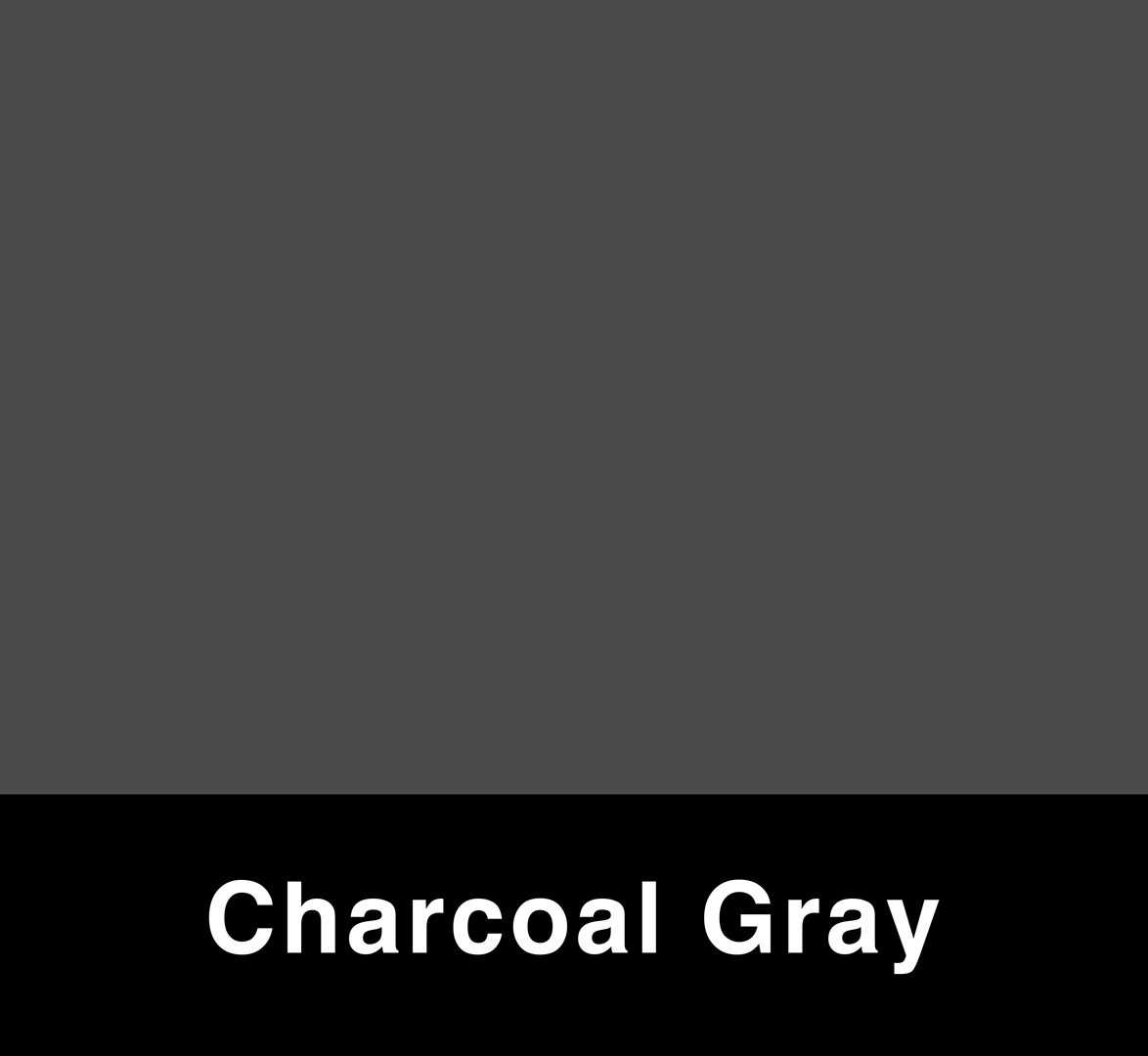

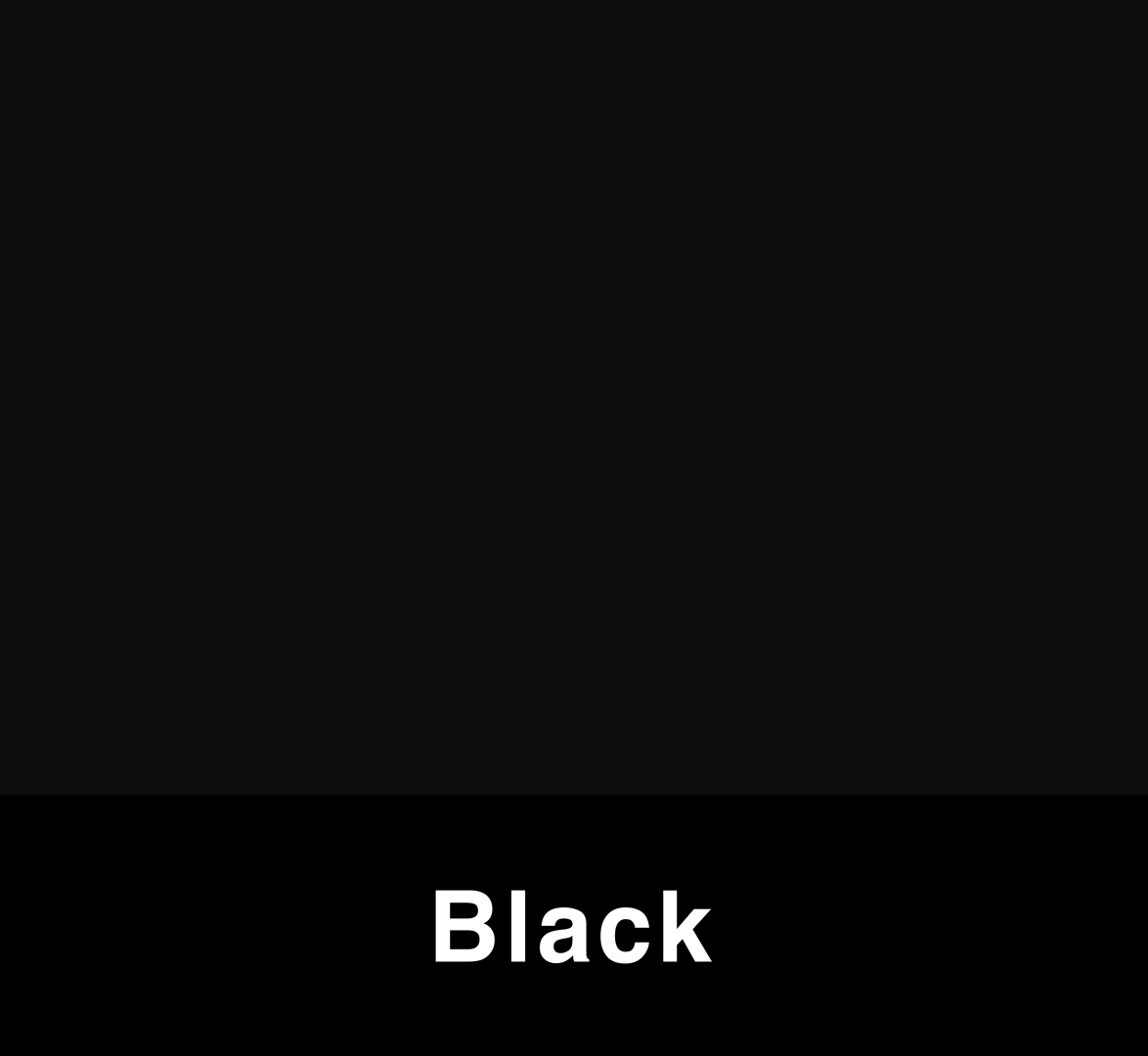

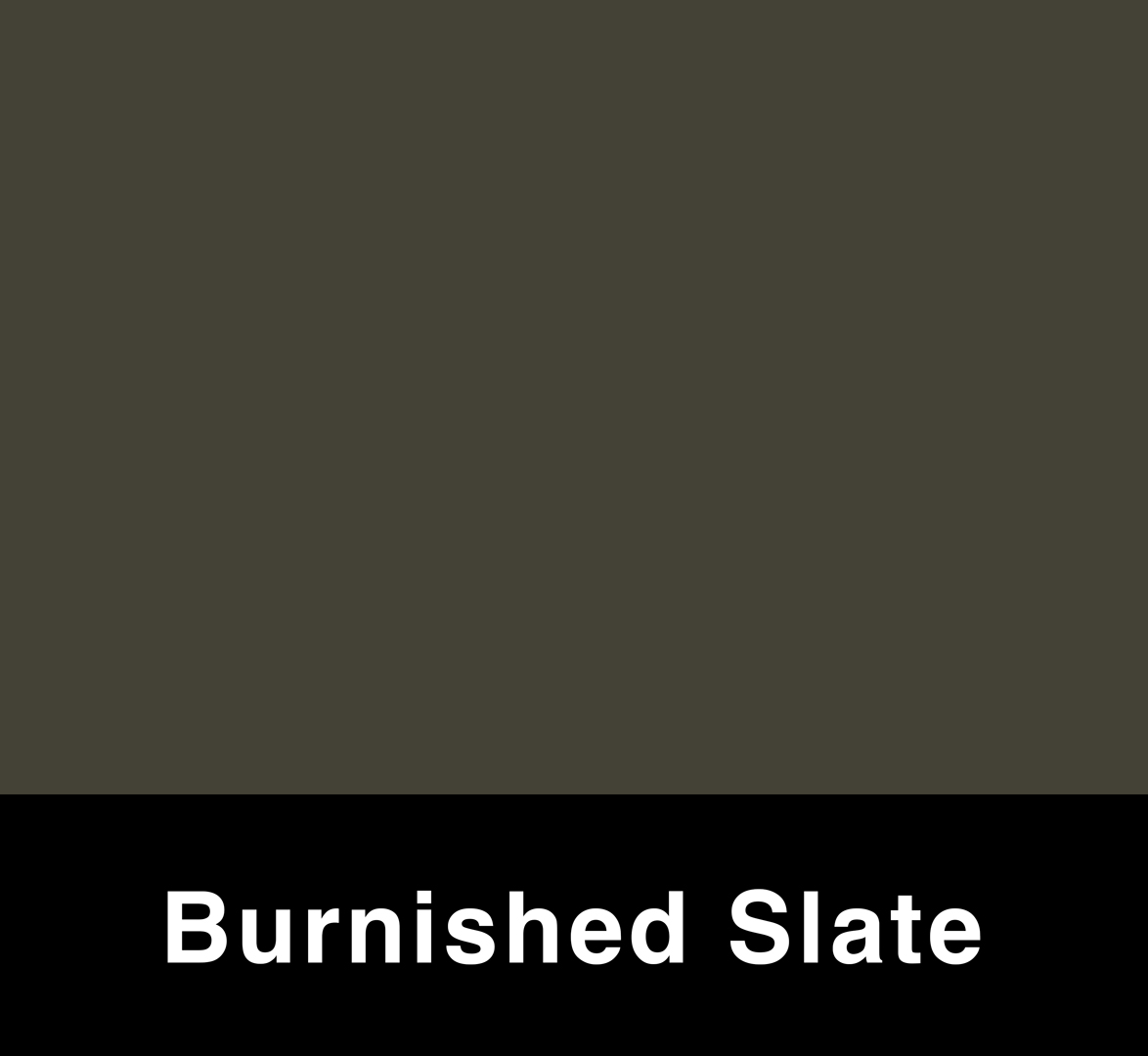

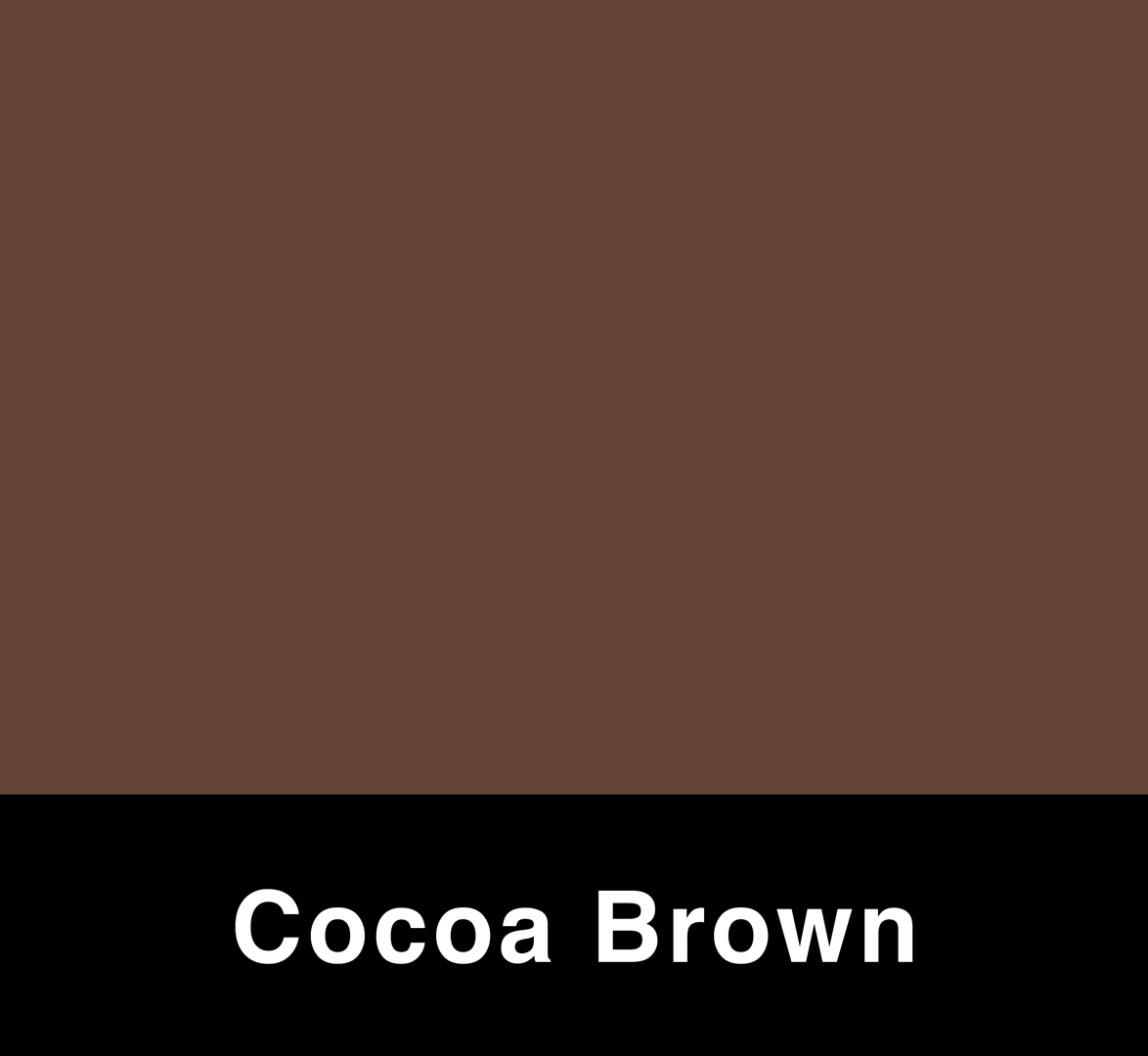

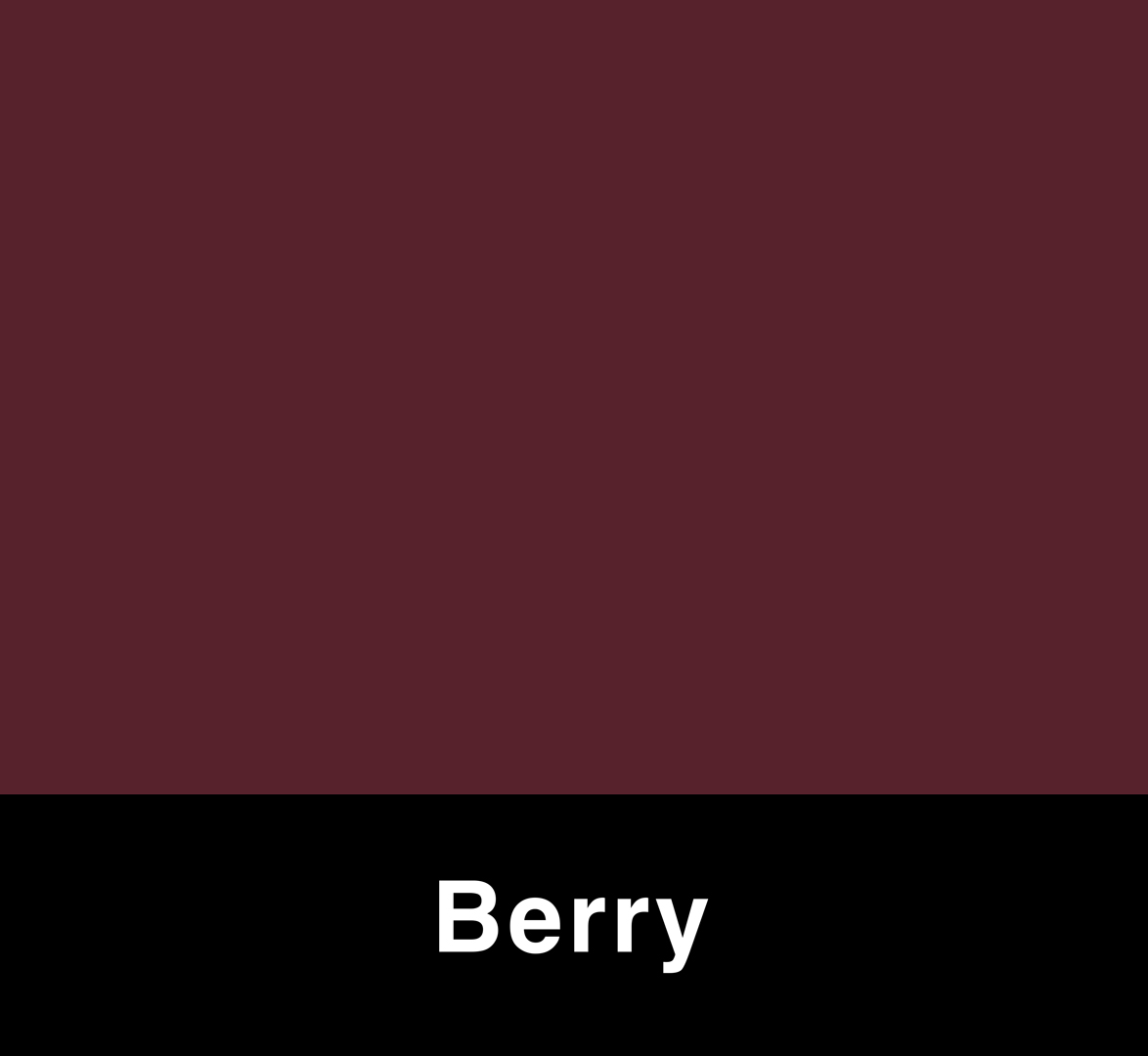

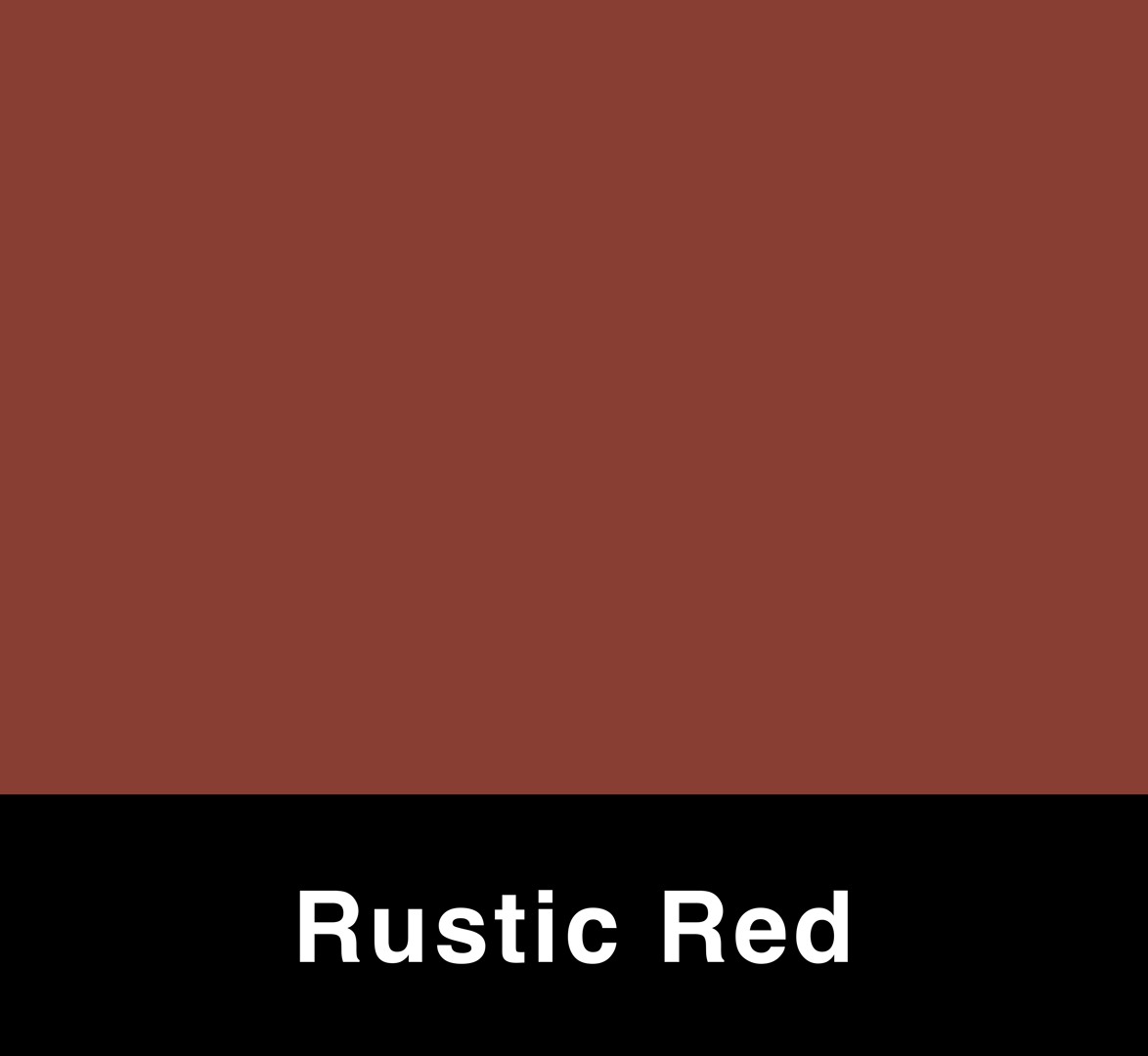

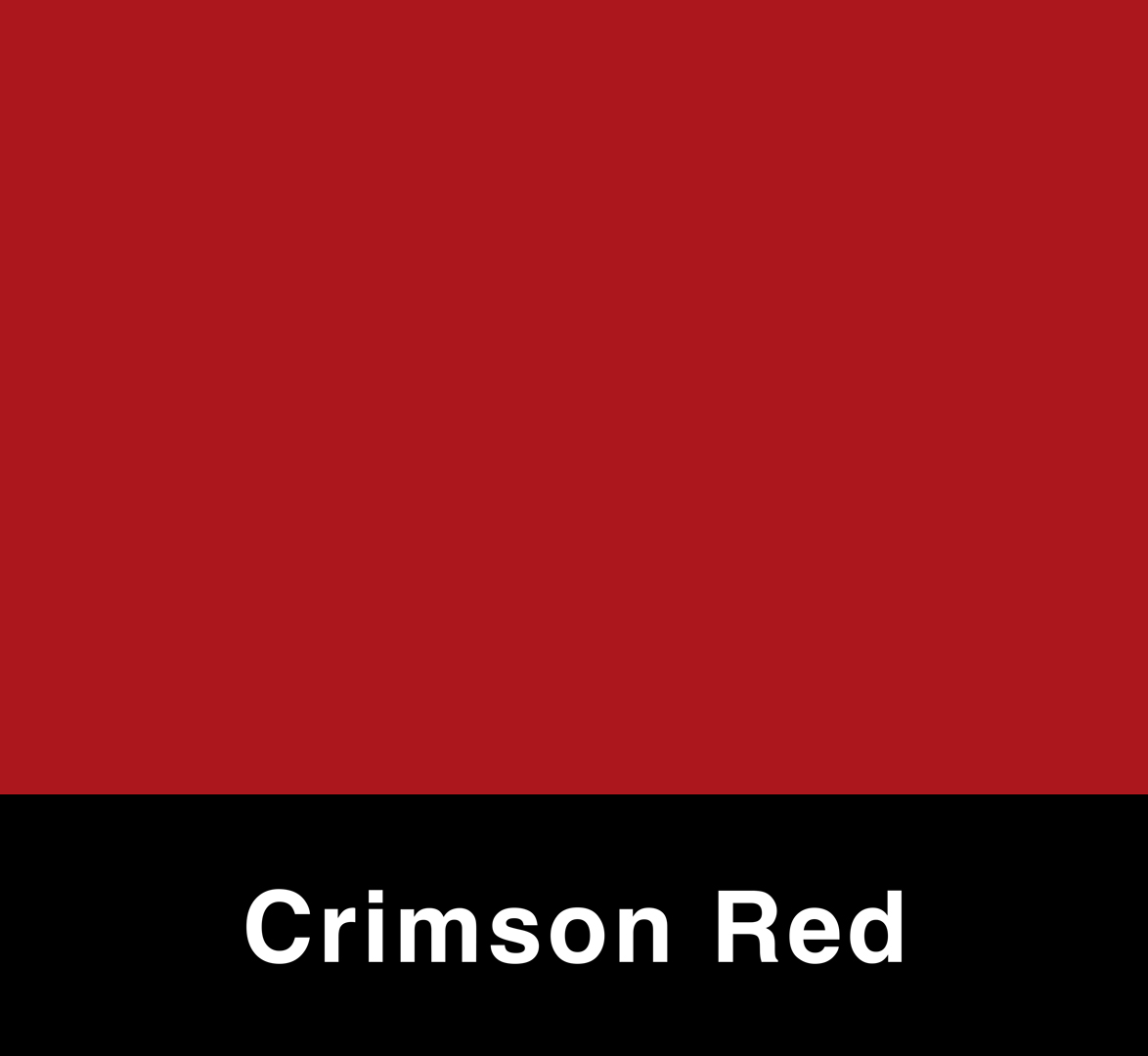

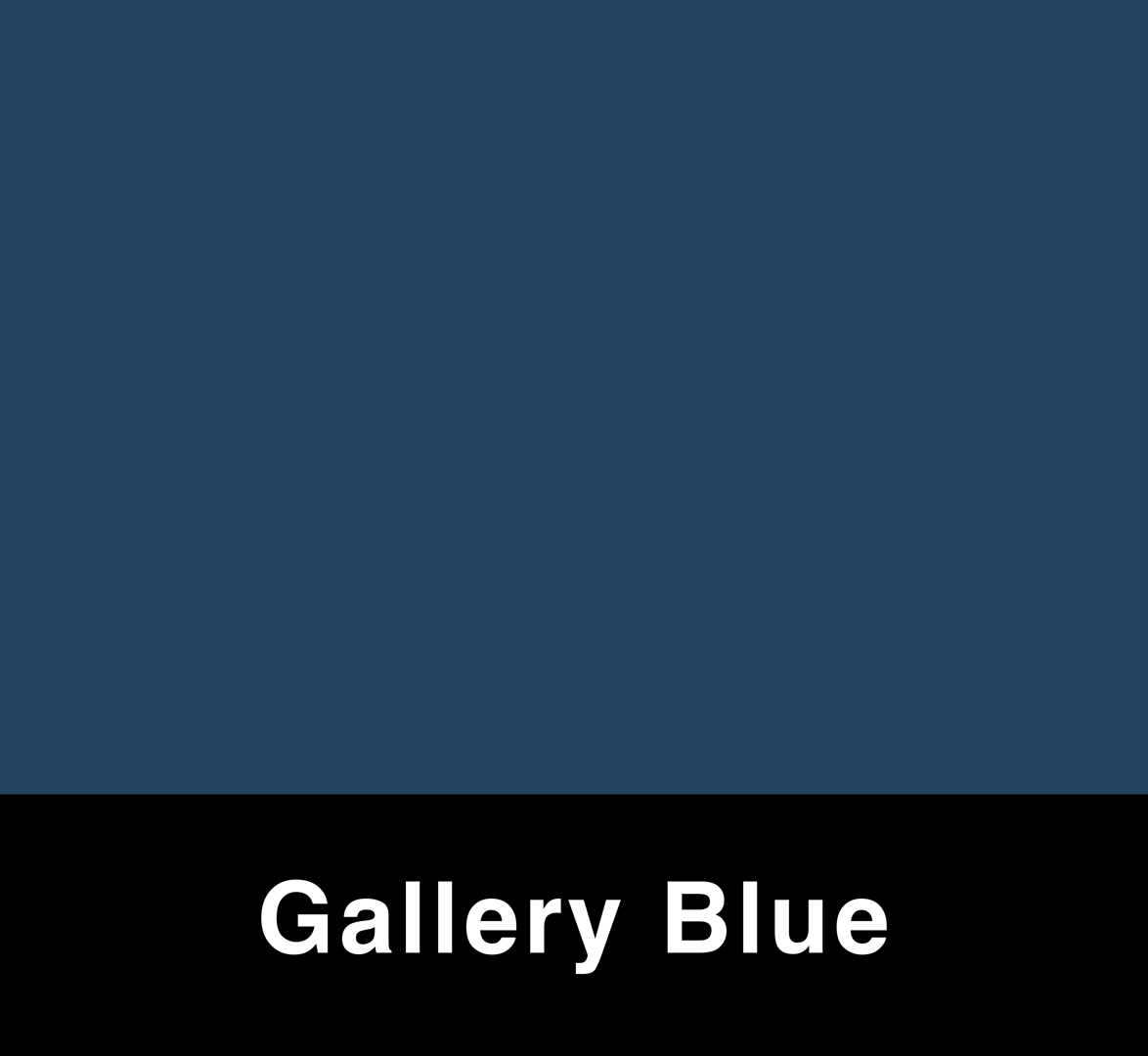

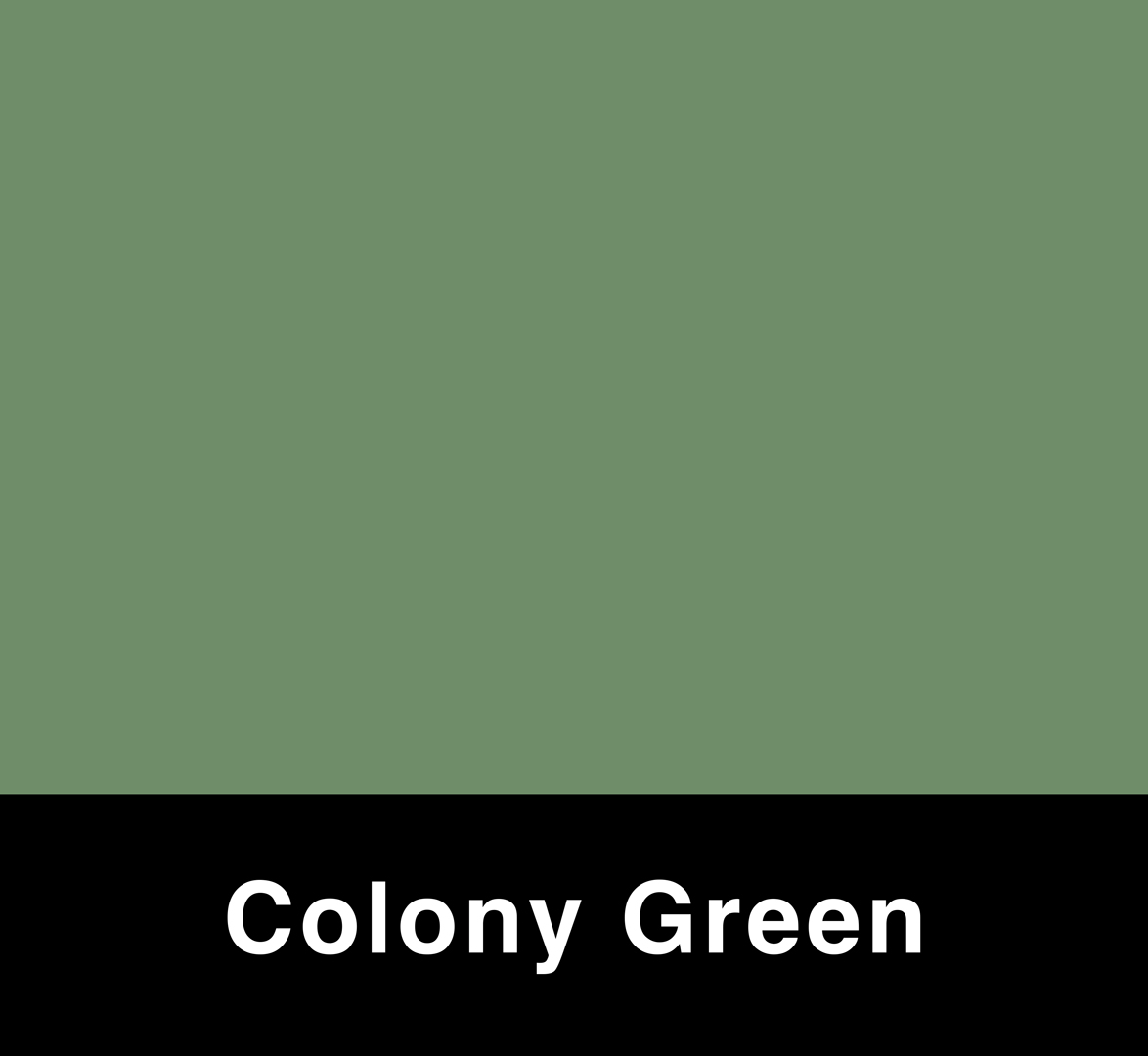

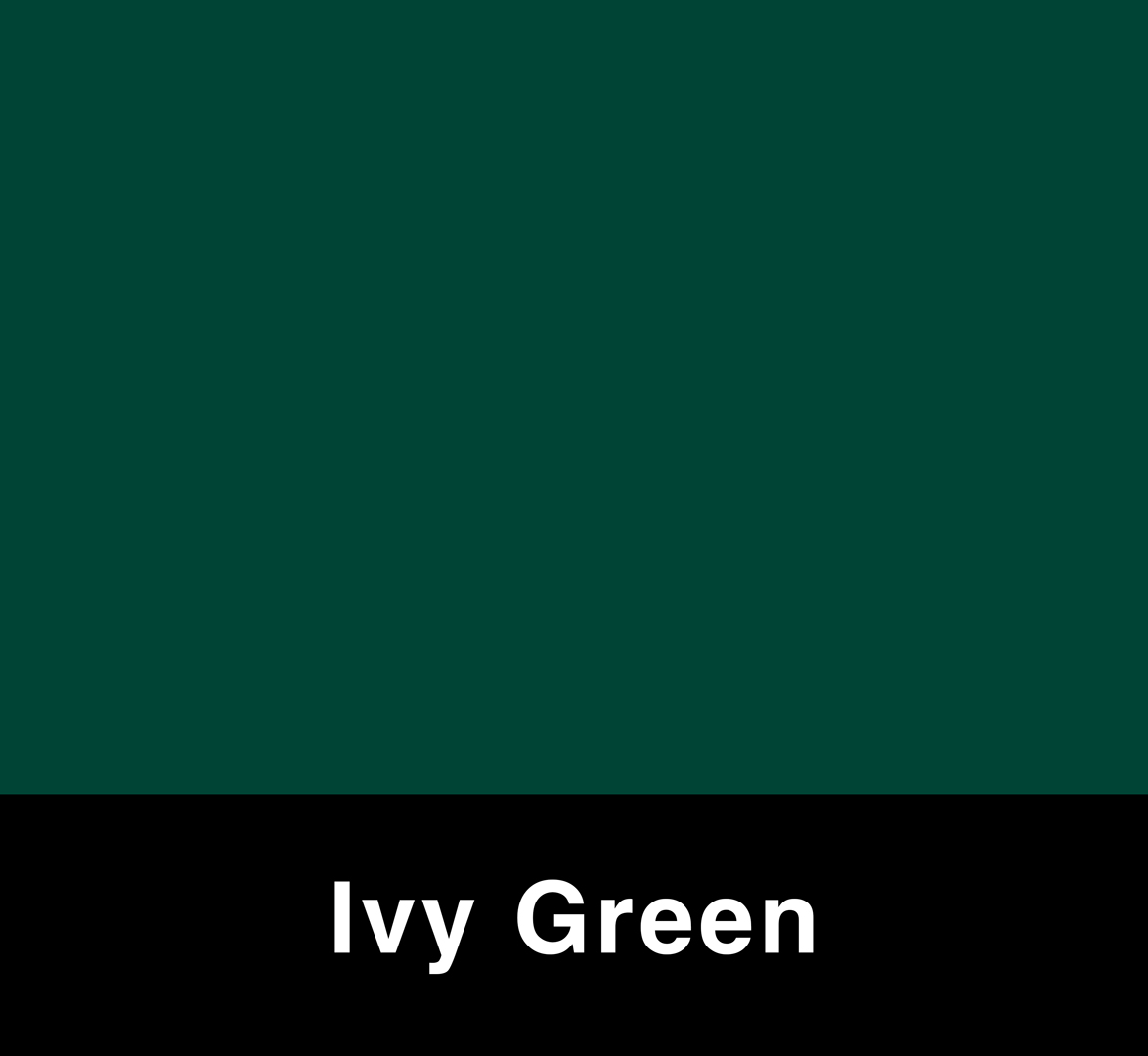

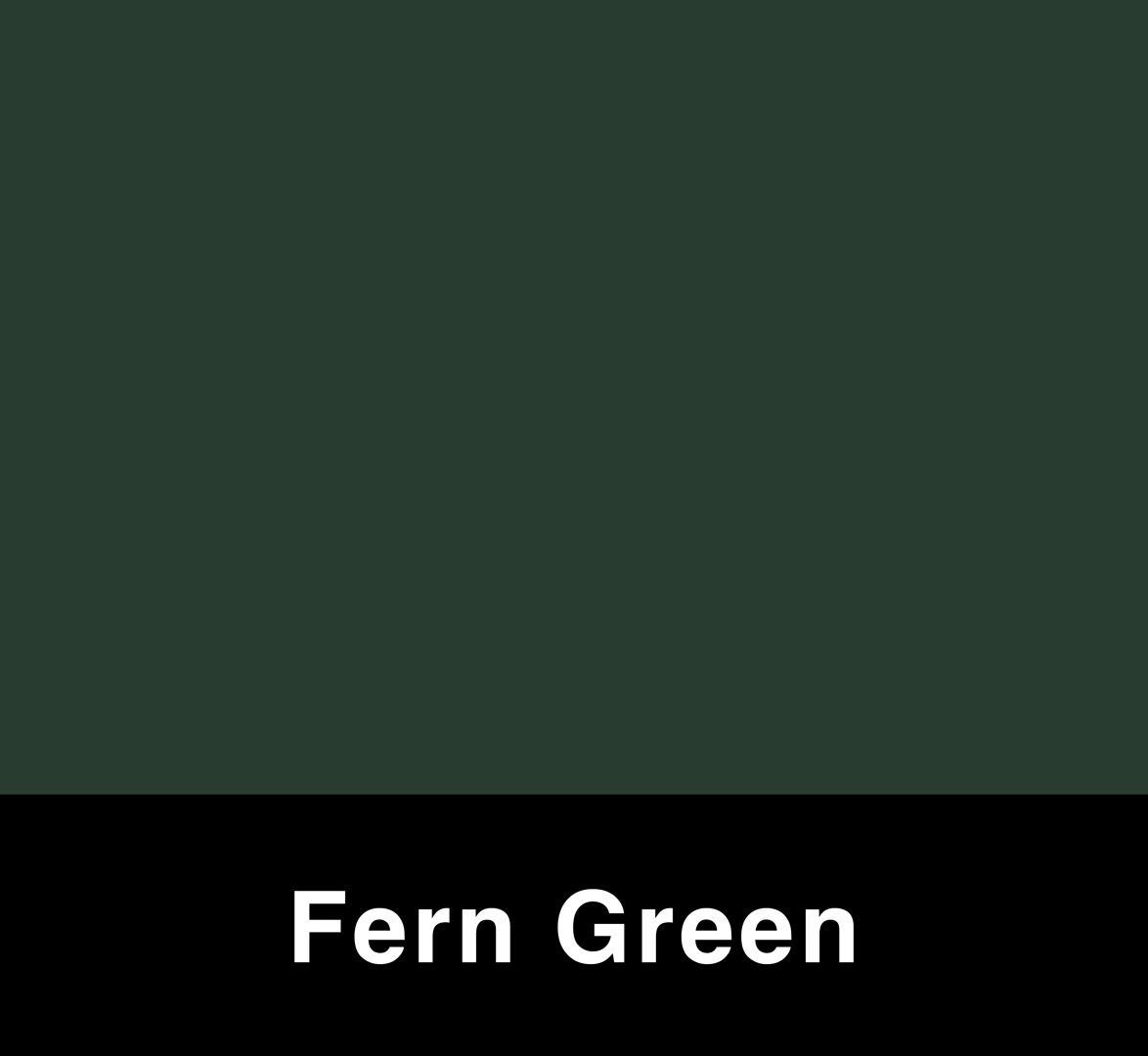

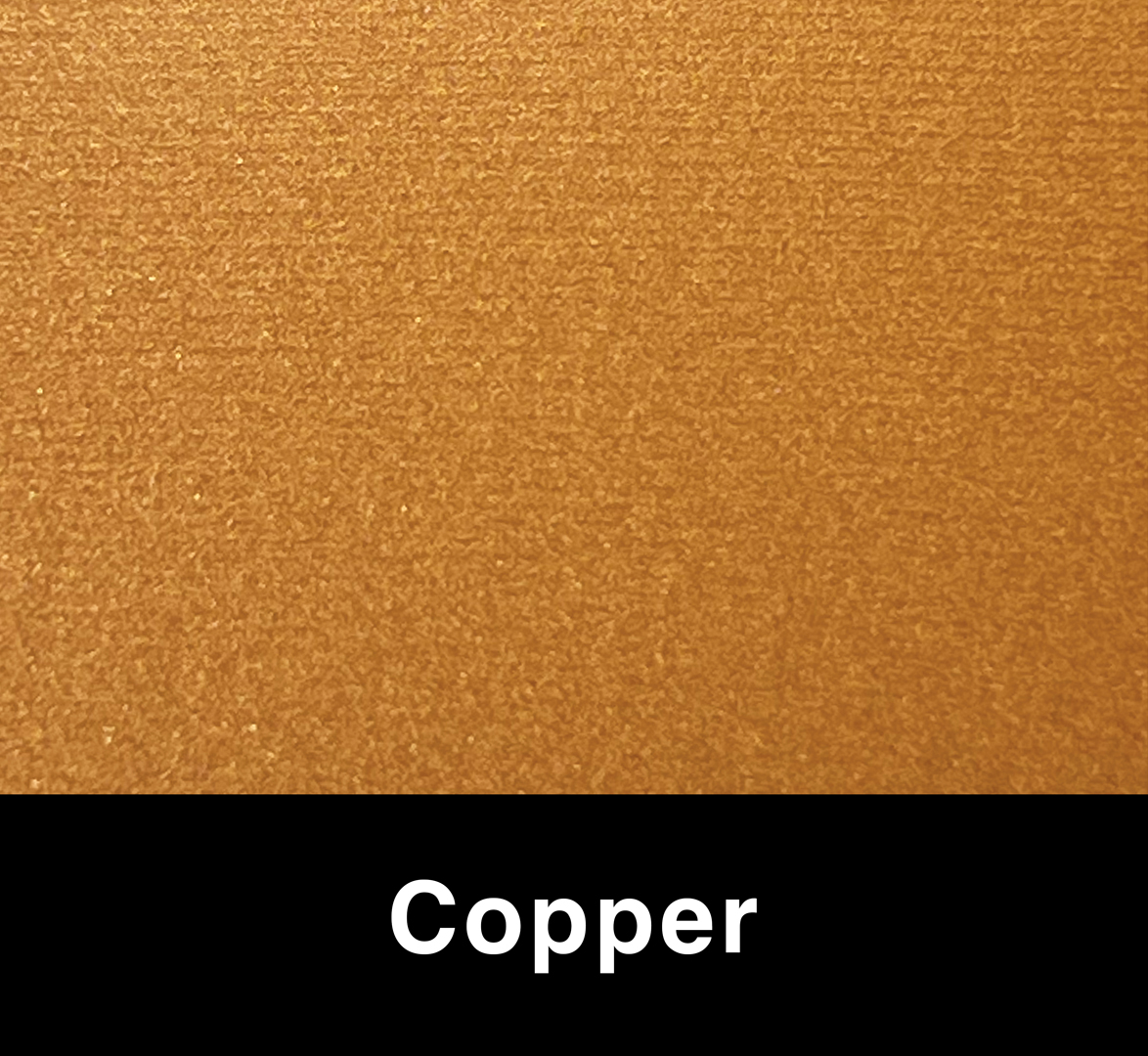

26 Gauge Colors

NOTE: Actual colors may vary from those displayed above. Visit your nearest MetalMax location to view actual metal color swatches.